SCHOTT Wins SPIE Catalyst Award for Hydrogen-Powered Glass Production

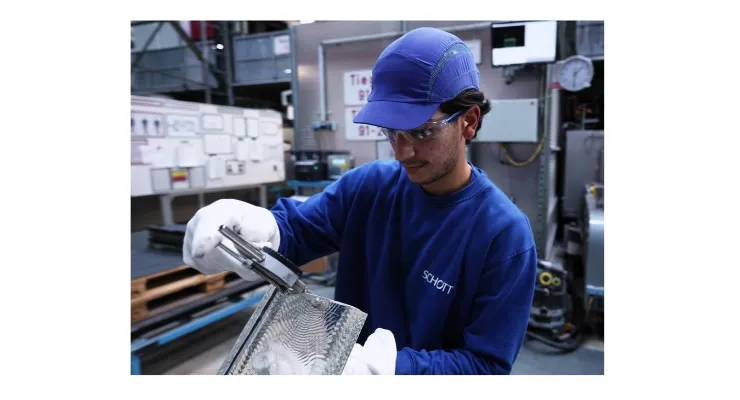

SCHOTT, the renowned international technology group and a pioneer in specialty glass, has been honored with the prestigious SPIE Catalyst Award for its groundbreaking innovation in producing optical glass using 100% hydrogen as a fuel source. This significant milestone represents a major step toward sustainable and carbon-free glass production, reinforcing SCHOTT’s commitment to decarbonizing industrial processes and reducing its environmental footprint.

A Revolutionary Shift in Glass Production

Glass manufacturing is an energy-intensive industry that relies on extremely high temperatures—often reaching up to 1,700°C—to melt raw materials and form high-quality glass. Traditionally, natural gas has been the primary fuel source for this process, leading to substantial carbon dioxide emissions. SCHOTT’s latest achievement demonstrates that hydrogen can successfully replace natural gas, providing a cleaner alternative without compromising the quality and performance of the final product.

Over the past six years, SCHOTT has dedicated extensive research and resources to developing hydrogen-fueled glass production methods. What began as small-scale laboratory experiments gradually evolved into full-scale industrial trials, culminating in a landmark three-day continuous production run in March. During this demonstration, SCHOTT achieved seamless transitions from natural gas to 100% hydrogen fuel while maintaining the same high glass quality that the company is known for worldwide.

Overcoming Technological Challenges

Transitioning from fossil fuels to hydrogen in glass manufacturing is a complex process that involves significant technical modifications and infrastructure adaptations. One of the critical challenges is ensuring stable combustion and uniform temperature distribution within the glass melting furnace. Hydrogen burns differently from natural gas, requiring specialized burner systems to maintain optimal performance and efficiency.

To support this transition, SCHOTT invested in state-of-the-art infrastructure, including a 5,000 Nm³ hydrogen storage tank and newly designed burner systems capable of handling pure hydrogen combustion. The company initially conducted a four-week trial using a 35% hydrogen admixture in one of its production tanks. Encouraged by the positive results, SCHOTT then proceeded with full-scale trials, successfully firing an optical glass melting tank entirely with hydrogen.

Industry Recognition and the SPIE Catalyst Award

The SPIE Catalyst Award, now in its second year, is an esteemed recognition presented by SPIE, the international society for optics and photonics. The award highlights organizations that demonstrate exceptional contributions to environmental sustainability and innovative technological advancements.

SCHOTT’s successful hydrogen-powered glass production trial places the company at the forefront of sustainable manufacturing in the optics and photonics industry. “Earning the SPIE Catalyst Award underscores our commitment to leading innovations for carbon-reduced glass production,” stated Jonas Spitra, Head of Sustainability Communications at SCHOTT. “This recognition reaffirms our belief that decarbonizing glass production is not only possible but essential for a sustainable future. At SCHOTT, we will continue to develop further technological solutions on our journey.”

The Road Ahead: Green Hydrogen and Policy Support

Despite these groundbreaking achievements, SCHOTT acknowledges that significant challenges remain in scaling up hydrogen-based glass production on a broader industrial level. Currently, the company relies on gray hydrogen—hydrogen produced using fossil fuels—due to limited availability and high costs associated with green hydrogen, which is derived from renewable energy sources.

“We have heavily invested in R&D and have proven that we can produce the same high-quality glass with hydrogen,” said Spitra. “However, the current lack of a viable infrastructure and competitive pricing for green hydrogen present challenges to further scaling up our testing and implementation. We urge policymakers to establish improved framework conditions to accelerate innovation and the adoption of sustainable energy sources.”

The global push for decarbonization has led many countries to invest in the development of green hydrogen production and infrastructure. If these initiatives gain momentum, SCHOTT will be well-positioned to integrate green hydrogen into its production processes, making its glass manufacturing operations even more sustainable.

A Broader Impact on the Glass Industry

SCHOTT’s achievement has far-reaching implications for the broader glass industry, which faces increasing pressure to reduce carbon emissions and embrace environmentally friendly practices. Glass is an essential material used in various industries, including architecture, automotive, electronics, and medical technology. As governments and industries worldwide intensify their climate action efforts, innovations like SCHOTT’s hydrogen-powered glass production can serve as a model for the entire sector.

By demonstrating the feasibility of hydrogen as a fuel for high-temperature industrial processes, SCHOTT’s initiative could pave the way for widespread adoption across the glass industry and other energy-intensive sectors, such as steel and cement manufacturing.

SPIE’s Recognition of Transformative Technologies

The SPIE Catalyst Award is part of the broader SPIE Prism Awards program, which celebrates groundbreaking innovations in optics and photonics. Each year, the Prism Awards highlight transformative technologies that have the potential to revolutionize industries and improve lives globally.

“Each year, the SPIE Prism Awards showcase a comprehensive range of innovative products based on optics and photonics technology,” said SPIE CEO Kent Rochford. “By bringing these optics and photonics-enabled products to market, these companies—the finalists as well as the winners—offer us transformative technologies that will impact lives across the world. It’s been a true pleasure to congratulate them in person.”

A Sustainable Future for Glass Manufacturing

SCHOTT’s achievement in developing hydrogen-powered glass production is a testament to the company’s dedication to sustainability and innovation. Since 2021, SCHOTT has been using 100% green electricity for its operations, and it continues to explore new ways to minimize its carbon footprint.

Looking ahead, SCHOTT aims to expand its sustainability initiatives, focusing on integrating renewable energy sources and enhancing energy efficiency in its production facilities. The company’s hydrogen research and development efforts mark a crucial step in its long-term goal of achieving carbon-neutral manufacturing.

SCHOTT’s pioneering efforts in hydrogen-powered glass production have set a new benchmark for sustainability in the industry. Winning the SPIE Catalyst Award recognizes the company’s commitment to driving technological advancements that support a greener future. While challenges remain, including the accessibility of green hydrogen and necessary policy support, SCHOTT’s success proves that decarbonizing high-temperature industrial processes is achievable.

As the world moves toward a low-carbon economy, SCHOTT’s innovation serves as an inspiring example of how industries can embrace clean energy solutions to reduce environmental impact while maintaining high product quality and efficiency. By continuing to push the boundaries of sustainable manufacturing, SCHOTT is helping shape the future of the glass industry and beyond.