FANUC America to Showcase Cutting-Edge Robotics and Automation Solutions at Automate 2025 in Detroit

FANUC America, a global leader in industrial automation, is set to demonstrate its latest innovations in robotics and automation at Automate 2025, a premier industry event to be held in Detroit from May 12-15. This year’s event promises to be an exciting showcase of FANUC’s most advanced robotic technologies, which are designed to enhance operational efficiency, reduce costs, and improve productivity for a wide range of industries. As manufacturers around the world continue to face challenges related to labor shortages and production demands, automation has become more critical than ever.

Mike Cicco, president and CEO of FANUC America, explained, “Today, more than ever, automation is the key to reaching production targets, boosting efficiency, and ensuring employee satisfaction. From start-ups to large-scale manufacturers, FANUC provides industry-leading, dependable, and cost-effective automation solutions that help companies overcome their greatest challenges.”

At Automate 2025, FANUC America will feature a broad selection of cutting-edge robotic technologies and automation solutions that highlight the company’s commitment to advancing the future of manufacturing. These solutions include collaborative robots (cobots), autonomous mobile robots (AMRs), advanced vision systems, and flexible automation solutions that cater to various industries, from automotive to electronics and beyond. Here are some of the standout technologies FANUC will showcase at the event.

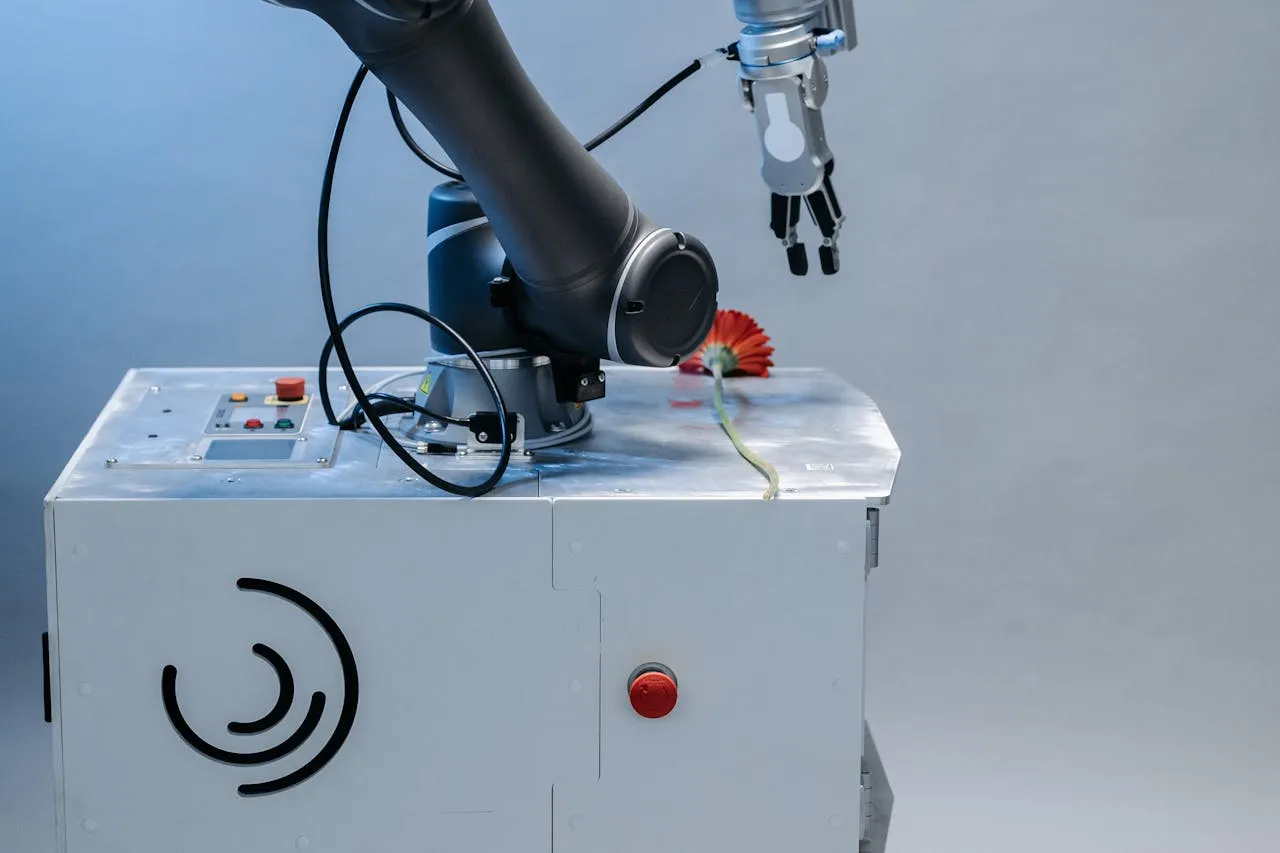

Collaborative Robots with Impressive Payload Capacities

FANUC’s collection of collaborative robots—or cobots—has been a significant breakthrough in the world of automation. The company’s cobots are designed to work safely alongside human operators, combining precision and flexibility with advanced sensors and programming. At Automate 2025, FANUC will display its entire line of cobots, including the CRX and CR series models, each of which is engineered to enhance productivity while ensuring safety in human-machine collaboration.

Notably, FANUC will highlight the CRX-10iA/L Paint Cobot, a specialized solution for applications such as painting, coating, and dispensing. This model is capable of handling payloads up to 50 kg and features a reach of 1,889 mm, allowing for highly flexible and adaptable operations in industrial settings. The CRX series is designed to be easy to use, making automation more accessible to manufacturers of all sizes, and it is especially beneficial in environments where repetitive or hazardous tasks are common.

Autonomous Mobile Robots for Automotive Kitting

In an exciting demonstration, FANUC will showcase its CRX-10iA/L Cobot mounted on a third-party autonomous mobile robot. This setup will demonstrate a cutting-edge automotive kitting solution. Using FANUC’s iRVision 3DV vision sensor, the system will accurately pick individual components of a vehicle’s side-view mirror and deliver the kit to a human operator for assembly and installation onto the door. This innovative application eases the labor process by eliminating the need for manual delivery of parts and kits to the assembly line, resulting in significant efficiency improvements and cost savings.

The use of autonomous mobile robots in manufacturing is rapidly gaining traction, and FANUC’s demonstration at Automate 2025 will provide valuable insights into the potential of AMRs to streamline operations and reduce human error in manufacturing environments.

Dual Cobot Paint Application with Load and Unload Functionality

In a demonstration that will highlight the versatility and precision of FANUC’s collaborative robots, the company will use two cobots to perform a dual paint application on electric guitar bodies. The CRX-10iA/L Paint Cobot will be equipped with FANUC’s 3DV camera and iRVision to visually track the guitar bodies during the painting process, while a CRX-20iA/L Cobot will leverage fixed vision sensors and advanced line tracking capabilities to load and unload the guitar bodies from a conveyor. This demonstration underscores the potential for collaborative robots to handle complex tasks such as painting, offering higher levels of consistency, repeatability, and quality control.

Collaborative Mobile Dispense Cart for Precise Adhesive Application

Another innovative solution that FANUC will showcase is its collaborative mobile dispense cart. This mobile dispensing system is equipped with FANUC’s Integral Servo Dispenser Software and cutting-edge adhesive metering equipment to provide precise, repeatable, and easily programmable adhesive application. Featuring a FANUC CRX-30iA Cobot with end-of-arm adhesive metering, this solution is designed to deliver exceptional control and repeatability in adhesive dispensing applications. It also utilizes FANUC’s 3DV/400 vision camera and SpotTool+ software to enhance the overall performance and flexibility of the system, making it suitable for a wide variety of industrial and manufacturing needs.

The mobile dispense cart is an example of how FANUC is working to bring automation to smaller-scale operations while still providing the high-performance solutions that large-scale manufacturers rely on.

Collaborative Arc Welding with Integrated 7th Axis Rail

One of the standout demonstrations at Automate 2025 will be FANUC’s collaborative arc welding system, integrated with a 7th axis rail. This solution uses the CRX-10iA/L Cobot in a two-station cell, where one station performs welding while the other is loaded by the operator. The addition of the 7th axis rail expands the work envelope, enabling more flexibility in the welding process. The system’s ability to load and weld parts concurrently improves throughput and reduces downtime, making it ideal for high-volume manufacturing environments.

This demonstration will also feature FANUC’s proven flexibility in manufacturing, showing how the company’s robotic solutions can adapt to a wide range of applications and industries.

Flexible Robotic Wet Machining Solutions

FANUC’s M800/60-20B industrial robot will be on display in a wet machining demonstration, where it will mill and drill aluminum stock using various tools. This high-precision robot is known for its rigidity, accuracy, and adaptability, making it a suitable alternative to traditional CNC machines. The robot’s ability to withstand harsh environments, such as exposure to water and debris, adds an additional layer of durability and functionality to its performance. With a larger work envelope than similarly priced CNC machines, this solution is perfect for manufacturers looking to increase precision while minimizing space constraints.

R-50iA Controller Technologies and Advanced Robotic Integration

FANUC will also showcase the advanced capabilities of its new R-50iA controller. This controller integrates seamlessly with FANUC’s LR Mate industrial robots, performing tasks such as bin picking and palletizing. The R-50iA controller also features cutting-edge cybersecurity protocols, including MQTT TLS, and utilizes a LDAPS server for user access control. Additionally, the controller includes Software PLC capability for cell control and HMI functionality, ensuring that operations remain smooth and secure. Attendees will see live demonstrations of the LR Mate/7-7D robot performing bin picking with FANUC’s 3DV/400 vision camera, while the LR Mate/7-9 long arm unit will showcase palletizing capabilities with the help of PalletTool Turbo II software.

This technology highlights the flexibility and advanced performance of FANUC’s robotic solutions, making it easier than ever for manufacturers to automate their operations and streamline production lines.

Educational and Interactive Experiences

In addition to its product demonstrations, FANUC will offer attendees the opportunity to engage with its robotics experts and leaders at a series of live events. These sessions will cover a variety of topics ranging from the state of the automation industry to the latest advancements in vision-guided robotics and robotic depalletizing. The following sessions will be available during the event:

- The State of the Automation Industry – Leadership Roundtable

Presented by America President and CEO Mike Cicco, Tuesday, May 13 at 12:30 p.m. ET - Cobot and Go: The Latest Trends and Tech Advancements Making Cobots More Accessible

Presented by FANUC America Manager Jerry Perez, Monday, May 12 at 1:30 p.m. ET - Advanced Vision Guided Robotics

Presented by FANUC Engineering Manager David Bruce, Wednesday, May 14 at 8 a.m. ET - Mastering the Complexities of Robotic Depalletizing

Presented by FANUC America Engineer Stacey Harimoto, Wednesday, May 14 at 10:15 a.m. ET - Panel: Equipping the Modern Workforce for Careers in Robotics, Automation, and Smart Manufacturing

Presented by FANUC America Executive Director, Education, Paul Aiello, Wednesday, May 14 at 1 p.m. ET - The Final Frontier of Automation in a High-Volume Automotive Paint Shop: Robotic Paint Repair on a Moving Line

Presented by America Senior Staff Engineer, Paint, Thomas VanderPlas, Tuesday, May 13 at 10:15 a.m. ET

FANUC America: A Legacy of Innovation in Automation

FANUC America Corporation, headquartered in Rochester Hills, Michigan, is a subsidiary of CORPORATION, Japan’s leading manufacturer of CNC systems, industrial robots, and ROBOMACHINEs. FANUC’s commitment to innovation and operational excellence has helped manufacturers maximize productivity, reliability, and profitability for decades. With a vast network of facilities across North and South America, continues to drive progress in the automation and robotics industries.

At Automate 2025, attendees will have the opportunity to witness firsthand how advanced robotics and automation technologies can revolutionize their operations, improve productivity, and increase competitiveness in an increasingly automated world. Don’t miss this chance to experience the future of manufacturing. Visit at Booth #2623 to see live demonstrations, interact with experts, and learn more about how these groundbreaking solutions can benefit your business.