Introduction to the Digital Transformation Initiative

ValGenesis, Inc. has announced that a prominent fill-finish contract development and manufacturing organization (CDMO) specializing in sterile filling operations has successfully adopted its advanced electronic logbook platform to modernize and streamline logbook management processes across its cutting-edge manufacturing facilities. This strategic move reflects a broader industry shift toward digital transformation within highly regulated pharmaceutical and biotechnology manufacturing environments. As sterile fill-finish operations become increasingly complex, the need for robust, scalable, and compliant data management solutions has become essential for maintaining operational excellence and regulatory readiness. The CDMO’s decision to transition from traditional paper-based logbooks to a cloud-enabled electronic system marks a significant milestone in its commitment to innovation, efficiency, and quality assurance.

Addressing the Challenges of Paper-Based Logbooks

The CDMO’s expansion into advanced robotic manufacturing lines and the deployment of increasingly sophisticated production equipment significantly increased the volume and complexity of operational documentation. Hundreds of paper logbooks were being used daily to record equipment usage, maintenance activities, environmental monitoring data, and critical process parameters. While paper documentation has long been standard practice in GMP-regulated environments, it presents several operational limitations, including manual errors, delayed data retrieval, storage burdens, and difficulties in scaling across multiple facilities.

As operations grew, managing these paper-based records became inefficient and increasingly difficult to control. Manual data entry introduced risks related to transcription errors, incomplete entries, and inconsistent documentation practices. Retrieving historical data for audits or investigations required significant time and labor, reducing overall productivity. Additionally, ensuring compliance with evolving regulatory requirements demanded more rigorous oversight and validation processes, further straining existing systems. The organization recognized that sustaining growth while relying on paper documentation would hinder agility and limit its ability to support clients efficiently.

Implementation of a Cloud-Based Electronic Logbook System

To overcome these challenges, the CDMO implemented the cloud-based electronic logbook application offered by ValGenesis. The platform is specifically engineered to meet the stringent regulatory and operational requirements of the life sciences industry, including Good Manufacturing Practice (GMP) standards. By replacing paper logbooks with a centralized digital system, the company has eliminated many of the constraints associated with manual record-keeping.

The electronic logbook enables real-time data capture, allowing operators to input information directly into secure digital interfaces using multiple device types. Automated compliance checks are embedded within workflows, ensuring that required fields are completed and that entries adhere to predefined validation rules. This structured approach significantly reduces the likelihood of documentation errors while enhancing data consistency across departments and facilities. Seamless traceability is another critical advantage, as digital records can be instantly retrieved, reviewed, and analyzed without the need for physical document searches.

Enhancing Compliance and Regulatory Readiness

Compliance remains a cornerstone of sterile fill-finish operations, where regulatory scrutiny is particularly stringent due to patient safety considerations. The implementation of ValGenesis’ electronic logbook system reinforces the CDMO’s quality management framework by embedding compliance directly into day-to-day processes. Automated time-stamping, electronic signatures, and audit trails ensure that every entry is securely recorded and traceable.

The application supports adherence to ALCOA+ data integrity principles, which emphasize that data must be Attributable, Legible, Contemporaneous, Original, Accurate, Complete, Consistent, Enduring, and Available. By digitizing logbook processes, the company strengthens its ability to demonstrate compliance during inspections and audits. Electronic records provide transparent documentation histories, simplifying the review process for both internal quality teams and external regulatory authorities. This proactive approach not only mitigates compliance risks but also builds trust with clients who rely on the CDMO to maintain the highest quality standards.

Scalability Across Global Operations

One of the most significant advantages of the cloud-based system is its scalability. As the CDMO continues to expand its operations and client portfolio, it requires a platform capable of supporting thousands of users across multiple global sites. The electronic logbook application is designed with this scalability in mind, enabling seamless deployment across diverse manufacturing environments.

The system’s architecture allows centralized oversight while maintaining site-specific controls, ensuring that global standards are upheld without compromising local operational flexibility. Additionally, the platform offers offline functionality tailored for secure and controlled manufacturing environments where internet connectivity may be restricted. This capability ensures uninterrupted operations while maintaining data integrity and compliance, even in isolated or high-security areas. As the organization scales, the digital infrastructure grows in tandem, eliminating the need for repetitive manual system expansions.

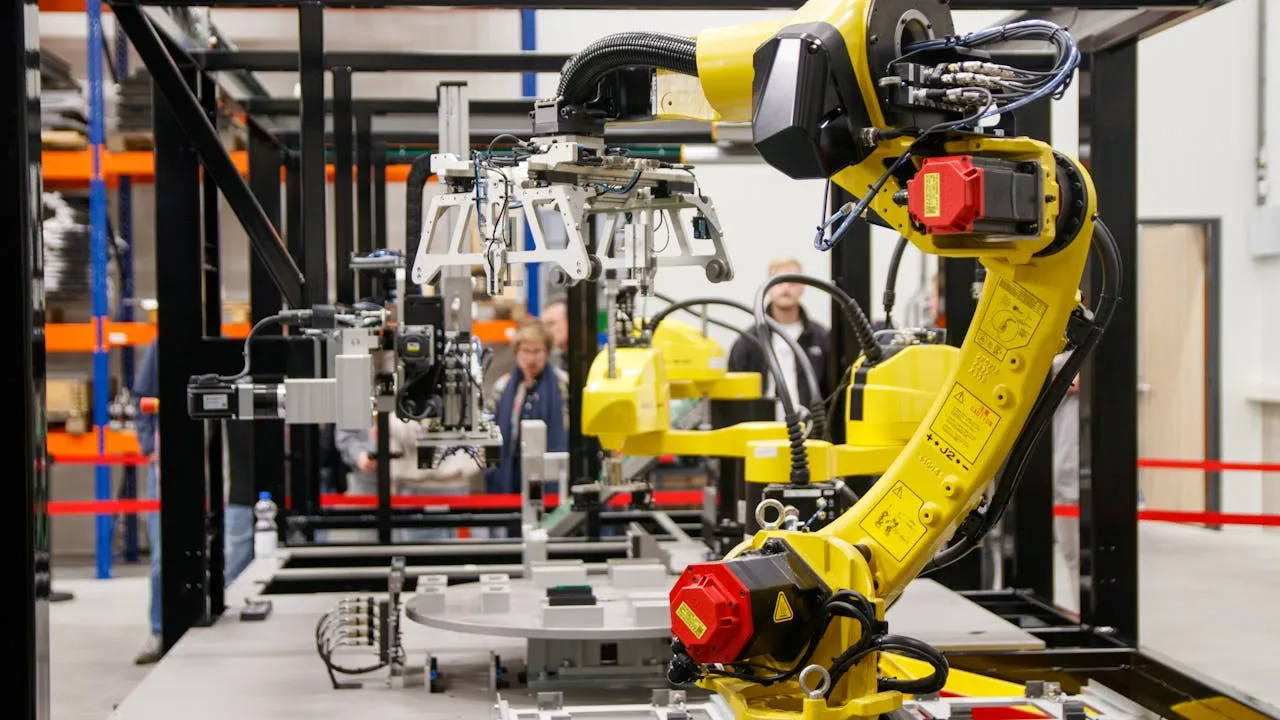

Supporting Advanced Robotic Manufacturing Lines

The CDMO’s investment in advanced robotic manufacturing lines reflects a commitment to automation, precision, and efficiency. However, sophisticated equipment generates large volumes of operational data that must be accurately documented and monitored. Integrating digital logbooks into these advanced manufacturing processes ensures that data generated by robotic systems can be captured systematically and linked to relevant batch records and equipment histories.

By aligning digital documentation with automated production systems, the organization enhances visibility into process performance and equipment utilization. Real-time monitoring supports faster issue identification and resolution, minimizing downtime and maintaining production continuity. This integration strengthens the synergy between automation and digital quality systems, creating a more resilient and responsive manufacturing ecosystem.

Optimizing Resource Utilization and Operational Efficiency

Beyond compliance and scalability, the transition to electronic logbooks significantly improves resource utilization. Paper logbooks require physical storage space, administrative handling, and manual archiving processes, all of which consume valuable time and resources. By eliminating these burdens, the CDMO can redirect personnel and infrastructure investments toward higher-value activities such as process optimization, innovation, and client engagement.

Digital workflows streamline review and approval processes, reducing cycle times and accelerating decision-making. Supervisors and quality personnel can access records instantly, facilitating quicker release of batches and faster responses to deviations. The improved efficiency directly contributes to shorter time-to-market timelines for clients, enhancing the CDMO’s competitive position in the marketplace.

Strengthening the Quality Management System

The adoption of ValGenesis’ electronic logbook application represents more than a technological upgrade; it reinforces the organization’s broader quality management system. By standardizing documentation practices and embedding automated controls, the company fosters a culture of accountability and continuous improvement. Data analytics capabilities within digital platforms can uncover trends, identify recurring issues, and inform strategic decision-making.

Improved data visibility empowers leadership to make evidence-based operational adjustments, driving higher levels of performance and reliability. As regulatory expectations continue to evolve, the digital infrastructure provides a flexible foundation capable of adapting to new requirements without disruptive overhauls. This future-ready approach ensures that quality remains central to growth and expansion strategies.

Executive Perspective on the Partnership

Steve Reynolds, Chief Revenue Officer at ValGenesis, expressed enthusiasm about supporting the CDMO’s digital transformation journey. He emphasized that replacing paper-based logbooks with a modern electronic system strengthens compliance frameworks, enhances operational efficiency, and ensures scalability as the organization continues to grow and adopt advanced manufacturing technologies. His remarks underscore the strategic value of digital transformation within the life sciences sector, where operational excellence and regulatory compliance are inseparable.

The partnership demonstrates how technology providers and manufacturing organizations can collaborate to address complex industry challenges. By aligning digital innovation with practical operational needs, both parties contribute to a more agile and resilient manufacturing landscape.

Positioning for Long-Term Growth and Innovation

As the sterile fill-finish CDMO advances its modernization initiatives, the adoption of ValGenesis’ electronic logbook platform positions the company for sustained long-term growth. Digital transformation is no longer optional in highly regulated industries; it is a strategic imperative. By proactively investing in scalable, compliant, and integrated digital systems, the organization ensures that it can meet increasing client demands while maintaining rigorous quality standards.

The transition from paper to digital logbooks symbolizes a broader evolution within pharmaceutical manufacturing. It reflects a commitment to innovation, operational excellence, and patient safety. Through enhanced traceability, improved data integrity, and streamlined workflows, the CDMO strengthens its ability to deliver reliable, high-quality sterile products to global markets. As advanced technologies continue to reshape manufacturing environments, digital platforms like those provided by ValGenesis will play a pivotal role in enabling sustainable growth and regulatory confidence.

Source Link:https://www.businesswire.com/