SWEP, a subsidiary of Dover and one of the world’s leading manufacturers of brazed plate heat exchangers (BPHEs), has announced the introduction of two major additions to its technology portfolio: the SWEP B327 and SWEP B224. These new heat exchanger models have been specifically engineered to address the rapidly growing global demand for efficient, compact, and scalable cooling solutions in modern data centers, as well as for advanced district energy systems. Their launch reflects both a technological milestone for SWEP and a strategic response to emerging market pressures driven by the accelerating adoption of Artificial Intelligence (AI), machine learning, and High-Performance Computing (HPC).

Meeting the Expanding Thermal Demands of the AI Era

Over the past decade, the nature of data center operations has fundamentally changed. As AI training models grow exponentially in size and complexity, and HPC applications expand across scientific research, financial modeling, autonomous systems, and cloud-based analytics, the power density inside server racks has increased dramatically. Traditional air-cooling systems, once sufficient for standard data processing workloads, are no longer capable of handling the extreme thermal output of today’s processors and graphics units. Liquid cooling—whether through direct-to-chip cooling, rear door heat exchangers, or coolant distribution units (CDUs)—has fast become a necessity.

SWEP’s newly introduced BPHE models, B327 and B224, are designed precisely for these environments. Both products expand SWEP’s already extensive lineup of liquid cooling solutions and are optimized for single-phase applications, which remain the preferred cooling method for many data center operators. They incorporate several shared design elements that directly address modern cooling challenges: large port configurations supporting high flow rates, low pressure drops to maintain system efficiency, and exceptionally high thermal performance within a compact footprint.

High Performance in a Compact Form: B327 and B224

The SWEP B327 and B224 heat exchangers are engineered to deliver a tight temperature approach, enabling effective heat transfer even within the constrained spatial layouts typical of data centers. As server densities continue to increase, data center managers are adopting CDUs more frequently to support liquid cooling loops that efficiently manage high-density heat loads. In these environments, every centimeter of available space matters, making SWEP’s compact BPHEs particularly advantageous.

Among the two models, the SWEP B327 stands out for its exceptionally high capacity. It can be used not only for direct data center cooling but also for heat capture and reuse applications, thermal energy storage, heating substations, and tap water stations with heat loads reaching up to 1000 kW. This flexibility allows the B327 to support broader sustainability initiatives—an increasingly important objective as data centers face mounting pressure to operate more responsibly and reduce environmental impact.

The SWEP B224, while smaller, offers similar benefits in terms of efficiency and adaptability. Its size makes it ideal for integration within tightly configured CDUs or mechanical cooling assemblies, contributing significantly to power usage effectiveness (PUE) improvements. Together, the B327 and B224 offer operators a range of options depending on their space limitations, cooling load requirements, and desired approach to heat reuse.

Aligning with Global Sustainability and Efficiency Trends

Ulrika Nordqvist, President of SWEP, emphasized the company’s commitment to supporting the technological transformation underway in global data infrastructure. “SWEP is committed to providing state-of-the-art heat transfer solutions to support the rapid evolution of data centers,” Nordqvist said. “Being at the forefront of market development and demand for products that meet the future of efficient, sustainable cooling and heat reuse is a core mission for SWEP. Both SWEP B224 and SWEP B327 reflect this goal.”

Her remarks highlight a crucial point: the increased focus on sustainability. As data centers continue to grow in number and scale, their energy consumption has gained significant attention from regulators, municipalities, and sustainability advocates. Heat reuse—capturing waste heat and redistributing it for district heating, industrial processes, or residential use—is becoming a priority for companies looking to reduce carbon footprints and improve energy efficiency.

SWEP’s new BPHE solutions are positioned to support precisely these sustainability strategies. By enabling highly efficient heat transfer and supporting heat recovery architectures, the B327 and B224 help turn what was once waste energy into a valuable resource.

A Comprehensive Portfolio for All Cooling Scenarios

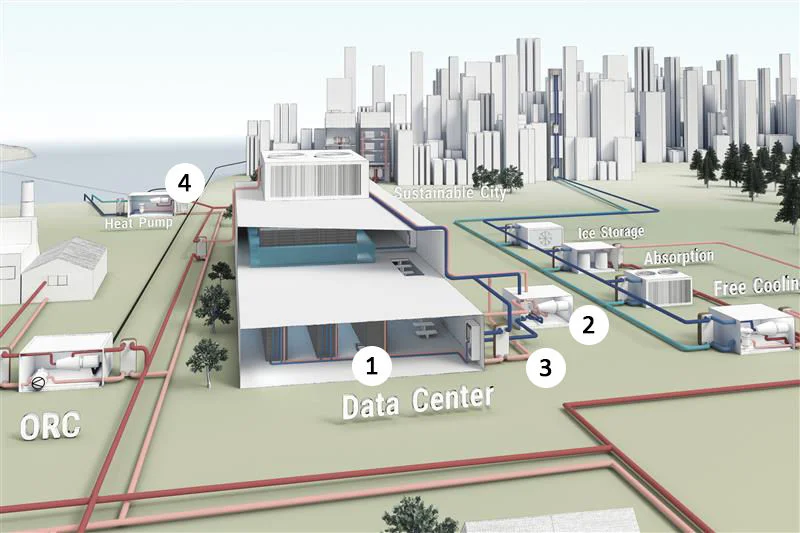

The introduction of these new models builds on SWEP’s existing portfolio of liquid cooling technologies, which covers a wide range of data center and district energy applications. The company’s solutions are designed to integrate seamlessly into several key systems:

1. Coolant Distribution Units (CDUs)

CDUs serve as the backbone of liquid cooling systems. They circulate coolant (such as a water-glycol mix) on one side of the heat exchanger and facility water on the other, delivering precise temperature control to high-performance servers. SWEP’s heat exchangers help ensure stable thermal transfer within these closed-loop systems, maintaining optimal temperatures even under heavy workloads.

2. Mechanical Cooling

SWEP’s BPHEs are also integral to chiller-based cooling systems, both air-cooled and water-cooled. They support Computer Room Air Handling (CRAH) units or supply facility water to CDUs in data centers transitioning to liquid cooling. Their efficiency and compactness help operators reduce energy usage while increasing capacity.

3. Free Cooling (Economizer Cooling)

Free cooling allows data centers to use naturally cold ambient air or facility water instead of mechanical chillers, drastically reducing energy consumption during certain climate conditions. SWEP heat exchangers are engineered for this mode, enabling operators to take advantage of outside temperatures to cool servers without relying solely on refrigerants.

4. Heat Recovery and Reuse

As sustainability becomes a defining feature of next-generation data center design, heat recovery systems are gaining traction. SWEP’s technologies enable operators to extract heat from server-cooled water streams and repurpose it for district heating networks, industrial facilities, agricultural operations, or building heating. This not only improves energy efficiency but can also generate economic benefits for operators through heat resale partnerships.

Supporting the Data Centers of the Future

The launch of the SWEP B327 and B224 underscores the company’s drive to provide innovative solutions for the world’s rapidly evolving digital infrastructure. As data centers continue to scale up, adopt AI workloads, and pursue more sustainable operations, the demand for advanced heat exchange technologies will continue to rise. SWEP’s latest products are built to meet these future challenges, balancing performance, reliability, and environmental responsibility.

In bringing these new BPHE models to market, SWEP reinforces its position as a leading partner to data center operators and district energy networks worldwide. With a focus on efficiency, compact design, and the ability to support both cooling and heat reuse, the SWEP B327 and B224 represent a significant step forward in thermal management solutions for high-performance digital environments.

Source link: https://www.dovercorporation.com/