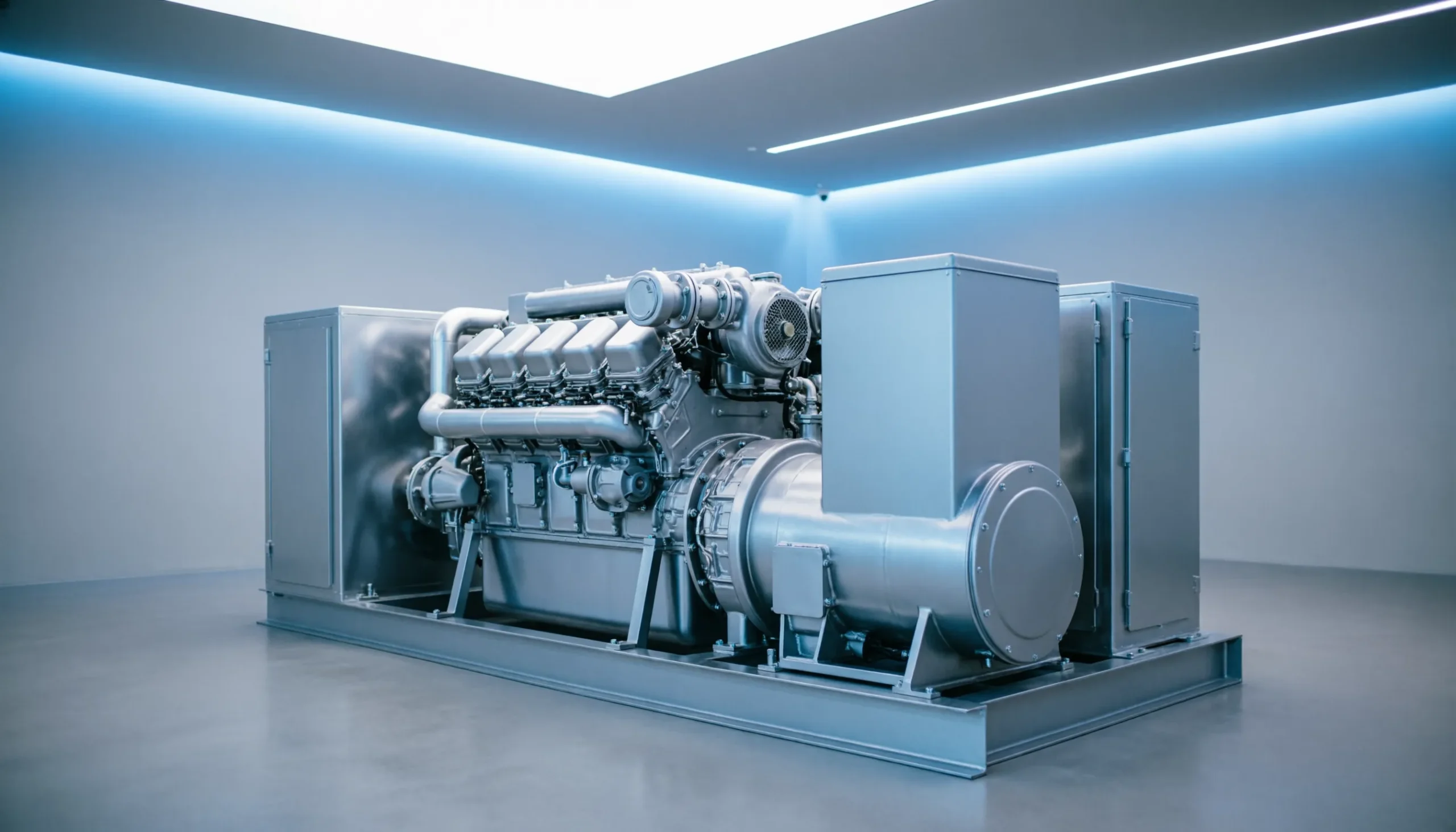

Rolls-Royce introduces modular gas engine power plants to support Germany’s evolving energy landscape

Rolls-Royce has unveiled a new modular solution for gas engine power plants designed to strengthen the security of electricity supply while accelerating the implementation of the German Government’s Power Plant Strategy. The turnkey facilities are engineered to deliver flexible power outputs ranging from as little as five megawatts to several hundred megawatts, depending on specific project requirements and grid demands. A defining characteristic of the solution is its readiness for hydrogen use, ensuring that the plants are compatible with future low-carbon fuel transitions as hydrogen infrastructure expands across Europe. By relying on preconfigured and factory-tested modules rated at 10, 20, and 30 megawatts, the company enables rapid deployment and simplified installation, allowing new power capacity to be connected to the electricity grid within approximately 12 to 18 months after an order is placed, a timeline significantly shorter than that of conventional large-scale generation projects.

Enhancing grid stability amid renewable energy variability

The newly introduced gas engine power plants are positioned as a crucial balancing technology for modern electricity systems increasingly dominated by renewable energy sources such as wind and solar. While renewables provide essential low-carbon generation, their variability can create substantial supply gaps during periods of weak wind or limited sunlight, sometimes lasting from several hours to multiple weeks. Rolls-Royce’s modular plants are intended to operate as dependable backup generation during these intervals, ensuring uninterrupted electricity availability for industries, infrastructure, and communities. In addition to backup functionality, the systems can serve as transitional or bridging power solutions in regions awaiting permanent grid connections or alternative baseload sources such as nuclear energy. Once long-term infrastructure becomes available, the gas engine units can seamlessly shift into standby or reserve roles, preserving investment value and maintaining operational flexibility for grid operators.

Presentation at E-world energy trade fair highlights strategic importance

Rolls-Royce is showcasing the modular gas engine concept at the E-world energy trade fair in Essen, scheduled from February 10 to 12, 2026, where the company is presenting the technology at booth 6H106 in Hall 6. The exhibition appearance underscores the strategic relevance of flexible, rapidly deployable generation assets in Europe’s ongoing energy transition. Industry stakeholders attending the event, including utilities, policymakers, technology partners, and energy-intensive businesses, are expected to evaluate how modular gas-fired capacity can complement renewable expansion while maintaining reliability and affordability. The timing of the launch aligns with intensified discussions across Germany and the broader European Union regarding capacity mechanisms, grid resilience, and the phased retirement of coal-fired power stations.

Leadership perspective on speed, economics, and partnership networks

Tobias Ostermaier, President of Stationary Power Solutions at Rolls-Royce Power Systems, emphasized that the modular gas engine approach enables rapid and cost-effective execution of Germany’s national power plant strategy. He highlighted the importance of an established partner ecosystem that supports swift project delivery while generating local economic value through regional engineering, construction, and service activities. According to Ostermaier, the widespread global adoption of Rolls-Royce stationary energy technologies—reflected in more than 17 gigawatts of installed capacity—demonstrates both technical maturity and operational reliability. Utilities, data centers, and industrial customers worldwide increasingly rely on flexible generation to safeguard operations against outages, fluctuating renewable output, and evolving regulatory requirements.

Combining resilience, affordability, and sustainability in decentralized systems

A central theme of the modular gas engine concept is the integration of resilience, cost-effectiveness, and environmental responsibility within a decentralized energy architecture. Rather than concentrating generation in a small number of very large power stations, the Rolls-Royce model distributes capacity across numerous smaller units that can be activated or deactivated individually based on real-time demand. This operational flexibility allows each engine to run at optimal efficiency, reducing fuel consumption, lowering emissions intensity, and improving overall economic performance. The environmental profile is further enhanced by compatibility with renewable gaseous fuels such as biomethane and biogas, enabling meaningful carbon footprint reductions even before the broader adoption of hydrogen.

Lessons from the United Kingdom’s capacity market transformation

Experience gained in the United Kingdom provides a practical reference for the effectiveness of modular gas-fired generation within an evolving energy system. Since 2014, the UK has relied on a capacity market framework to support the transition away from coal toward renewable and gas-based electricity production. Rolls-Royce has played a significant role in this shift by supplying highly efficient mtu gas gensets that reinforce grid reliability during peak demand and renewable shortfalls. Approximately 500 such gas gensets are currently deployed across the British power network, collectively contributing to system stability while enabling continued expansion of wind and solar resources. This operational track record offers valuable insights for Germany and other nations pursuing similar decarbonization pathways, combined with strong security-of-supply requirements.

Decentralization as a foundation for true energy resilience

Michael Stipa, Senior Vice President for Strategy, Business, and Product Development within Rolls-Royce’s Stationary Energy Solutions division, underscored the strategic importance of decentralization in modern power systems. He argued that resilience is more effectively achieved through distributed generation structures than through reliance on a limited number of centralized facilities vulnerable to large-scale disruptions, transmission bottlenecks, or single-point failures. Modular gas engine plants embody this decentralized philosophy by creating a network of flexible generation nodes capable of responding rapidly to changing grid conditions. Such architecture enhances reliability not only during routine variability but also in extreme scenarios such as severe weather events, infrastructure damage, or sudden demand spikes.

Supporting industrial electrification and digital infrastructure growth

Beyond grid stabilization, modular gas engine plants are increasingly relevant to sectors experiencing rapid electricity demand growth, including data centers, advanced manufacturing, and hydrogen production. These industries require highly reliable, high-quality power supplies that can be deployed quickly and scaled alongside operational expansion. Rolls-Royce’s modular configuration allows incremental capacity additions without the long development timelines associated with conventional power stations, making it particularly attractive for fast-moving digital and industrial investments. The hydrogen-ready design also aligns with long-term decarbonization strategies pursued by corporations seeking to reduce Scope 1 and Scope 2 emissions while maintaining operational continuity.

Accelerating the pathway toward hydrogen-enabled energy systems

Hydrogen readiness represents a forward-looking dimension of the Rolls-Royce solution, reflecting expectations that hydrogen will become a significant energy carrier in Europe’s future low-carbon economy. By ensuring compatibility with hydrogen blends and eventual full hydrogen operation, the modular gas engine plants protect customers from technology obsolescence and regulatory uncertainty. This adaptability supports phased decarbonization, allowing operators to begin with natural gas or renewable gaseous fuels and progressively transition toward hydrogen as supply chains mature and costs decline. Such flexibility is widely regarded as essential for balancing climate ambitions with economic and reliability considerations.

Europe’s flexible generation requirements

As Europe continues to expand renewable energy capacity while retiring fossil-based baseload generation, demand for flexible, dispatchable power solutions is expected to grow substantially. Modular gas engine plants—particularly those capable of operating on low-carbon fuels—are positioned to play a bridging and balancing role throughout this transition period. Rolls-Royce’s latest offering illustrates how engineering innovation, modular construction, and fuel flexibility can converge to address the complex challenges facing modern electricity systems. By combining rapid deployment, decentralized resilience, and future hydrogen compatibility, the technology contributes to a broader vision of secure, sustainable, and economically viable energy for Germany and beyond.

Source Link:https://www.rolls-royce.com/