Peak Technology Launches APEX to Transform OEM Collaboration in Advanced Manufacturing

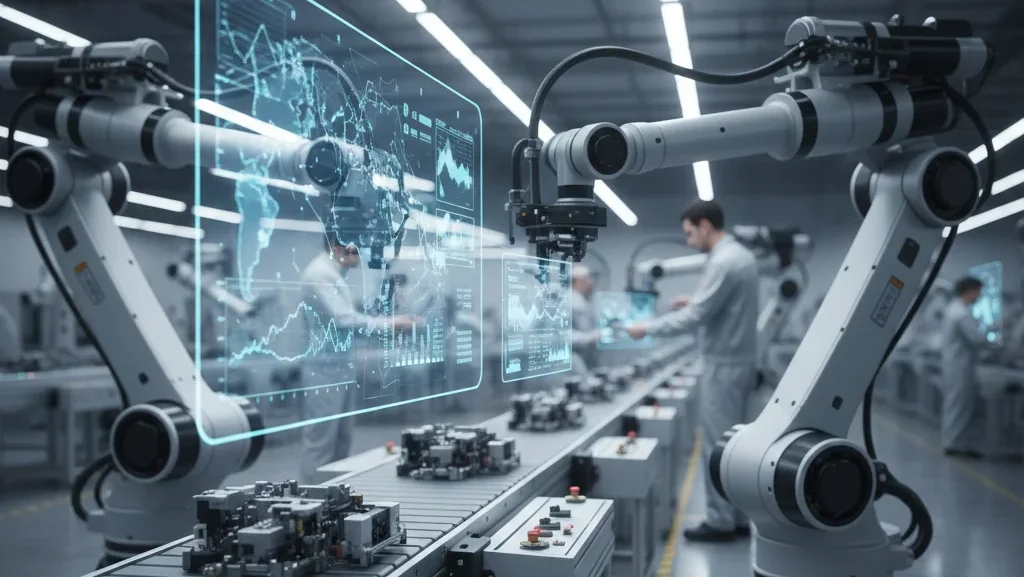

As advanced manufacturing accelerates under the forces of Industry 4.0, deep tech OEMs are under increasing pressure to move faster—from rapid prototyping to high-volume production—without sacrificing precision, traceability, or supply chain intelligence. Addressing this challenge head-on, Peak Technology has unveiled APEX, a proprietary Product Development and Realization Platform designed to redefine how OEMs collaborate, scale, and execute in next-generation manufacturing environments.

A Platform Built for the Era of Industry 4.0

Peak Technology, a recognized leader in quick-turn prototyping and advanced manufacturing for the Semiconductor, Bio-Medical, Aerospace, and other deep tech sectors, developed APEX in response to a fundamental shift in OEM expectations. Today’s manufacturers are no longer looking for transactional suppliers—they are seeking systems-level partners capable of integrating directly into their operations.

Peak describes this shift as the Mechanization of the Internet, where AI-driven, robotic-centric, and highly complex products require manufacturing platforms that are deeply connected, responsive, and intelligent. APEX was engineered precisely for this environment.

What Makes APEX Different

Unlike traditional fulfillment or manufacturing execution tools, APEX is designed to enable true OEM-to-OEM collaboration. The platform formalizes Peak Technology’s manufacturing expertise into a system that integrates seamlessly with customer operations, delivering speed, transparency, and operational alignment.

According to Sharon Woo, Founder & CEO of Peak Technology, APEX goes far beyond order execution. It enables Peak to anticipate customer needs, align with internal planning systems, and scale production with the agility demanded by modern manufacturing. This level of responsiveness is critical as product lifecycles shorten and customization becomes the norm.

Full-Spectrum Manufacturing, Fully Integrated

At the core of APEX is a unified system that connects every stage of the manufacturing journey. The platform brings together:

- Product lifecycle management

- Production scheduling and forecasting

- Vendor coordination and material sourcing

- Manufacturing engineering workflows

- Customer-specific documentation and compliance

By consolidating these functions into a single, responsive platform, APEX turns complex manufacturing requirements into scalable, repeatable delivery programs. Dedicated engineering touchpoints, transparent forecasting, and customized logistics ensure that Peak’s customers experience seamless execution—from prototype to production.

Strengthening Vertical Integration and Additive Manufacturing

APEX also builds on Peak Technology’s recent expansion in additive manufacturing, reinforcing its position as a vertically integrated partner for OEMs navigating digital transformation. This integration enables tighter control over quality, timelines, and traceability—key factors for industries where precision and compliance are non-negotiable.

Robert de Neve, COO & Head of Corporate Venture at Peak, emphasizes that APEX connects Peak to customers not just at the project level, but at the operational and planning level. This infrastructure supports what Peak calls full-spectrum manufacturing—a collaborative, traceable, and fully integrated approach to product realization.

Enabling the Future of Advanced Product Development

As AI, robotics, and automation continue to reshape manufacturing, platforms like APEX will play a critical role in enabling OEMs to innovate faster while maintaining operational discipline. By embedding itself into customer workflows, Peak Technology positions itself as more than a manufacturing partner—it becomes an extension of the OEM’s internal system.

About Peak Technology

Peak Technology Enterprises is a woman-owned precision manufacturing technology company based in San Jose, CA, offering additive and subtractive manufacturing, engineering support, system integration, and full assembly services. With over 60 years of experience and ISO 9001 certification, Peak partners with global OEMs and innovators to deliver high-performance components and complex builds—on time, on spec, and on budget. Peak Technology provides the following services to Original Equipment Manufacturers (OEMs) worldwide building complex electro-mechanical, optical, and mechatronic products and equipment:

APEX Solutions

- Innovative Manufacturing – Materials Science, Selection, & Design for Manufacturing (DFM)

- Formative Manufacturing – Forming, Fabrication & Welding

- Additive Manufacturing – 3D Printing & Scanning

- Subtractive Manufacturing – Automated, Multi-Axis, CNC Machining

- Integrative Manufacturing – Cleanroom-Based Assembly, System Integration & Product Support

Additional information may be found at www.peakfab.com.