Stratasys Ltd. (Nasdaq: SSYS), a leader in polymer 3D printing solutions, today announced that the German service bureau PartsToGo has invested in another four stereolithography (SLA) printers. They selected three Neo800 printers and one Neo450 to complement their existing Neo450 and Neo800 to produce high-quality, accurate, and repeatable parts for their customers’ industrial-level application needs. The investment brings PartsToGo’s total Neo fleet to six systems, with a seventh Neo planned for installation in the next few weeks.

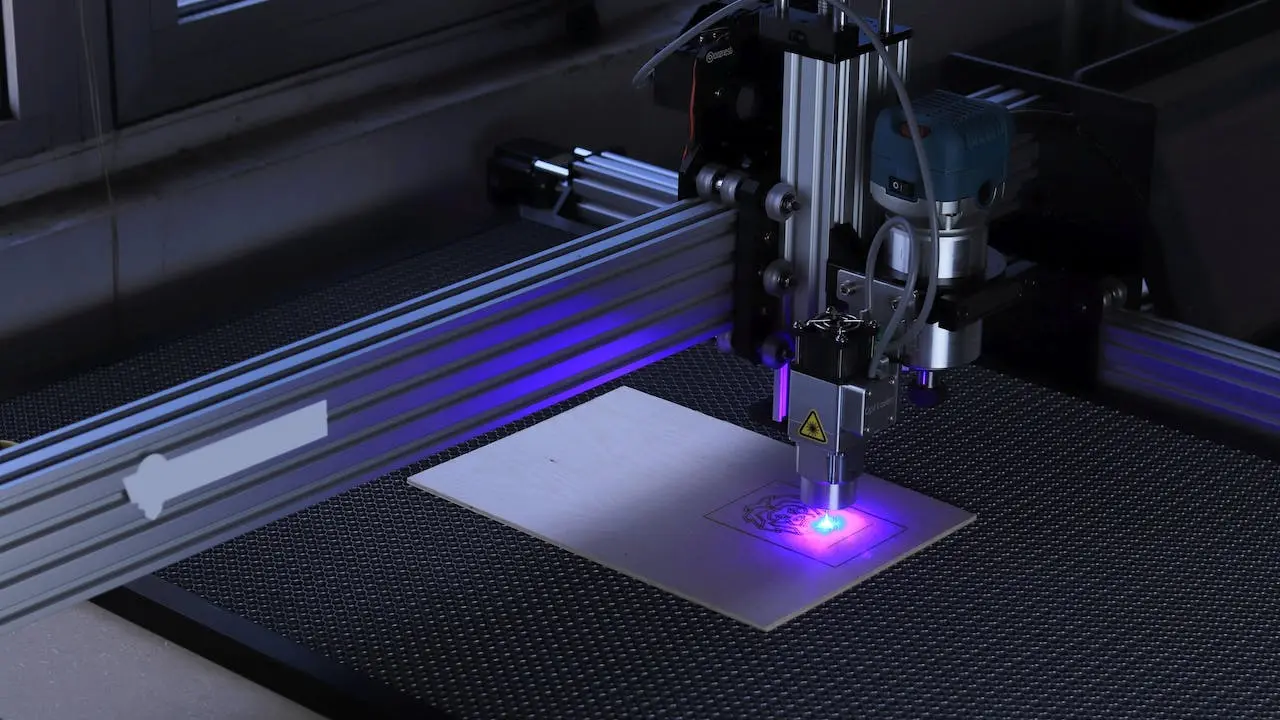

These Neo printers will play the leading role at a new specialist facility that PartsToGo has established in the Black Forest region. This facility, which opened its doors at the start of this year, offers 24/7 production and features updated logistical capabilities, a dedicated showroom, as well as two automation cells for scaling 3D printing production.

PartsToGo has evolved from an operation geared toward demonstrating 3D printing capabilities to customers, to a full-fledged service bureau. This was spurred by an increasing demand among customers without in-house additive manufacturing expertise, or those who lacked the production requirements to warrant investment in their own 3D printer.

The ability to create large, high-quality parts, with an open material system on our Neo printers has led to many new business opportunities for our company,” said Tobias Röcker, CEO of PartsToGo. “Our additional printers allow us to scale production to meet the rapidly growing market needs while smartly managing our operational costs.”

According to Röcker, the Neo printer’s stereolithography-based resin technology is critical to creating the high-quality, repeatable parts expected by customers.

A large part of our customer base is in the automotive industry, a sector in which accuracy, reliability, and repeatability are paramount,” he noted. “Investing in accurate, high-quality systems like the Stratasys SLA solution empowers us to expand our 3D printing operation, moving it from a side project to its own standalone business. Beyond automotive, we also serve many other industrial customers, including those with packaging and electrical application needs, providing small series production for prototyping, testing, and fixtures.”

Essential to PartsToGo’s ability to deliver high-quality resin models are the Stratasys materials Somos® WaterShed XC 11122 and Somos® WaterShed Black. These are versatile resins that deliver detailed parts with water resistance and a smooth finish, ultimately accelerating testing time. PartsToGo also uses Somos® PerFORM for applications requiring a stronger, stiffer material with high heat resistance, such as tooling and electrical casings.

The superior quality and part consistency of our Neo printers have not gone unnoticed by our customers who have responded very positively. In many cases we were even able to convince customers who previously used other suppliers of our quality,” Röcker summarized.

PartsToGo enjoys maximum flexibility in its choice of materials thanks to the open material system of the Neo series. Finishing time is reduced by up to 50% due to the quality, speed, and detail, which ensures the production of highly accurate and repeatable parts.