Mativ Secures First Commercial Order for Advanced Materials Powering Miru’s Revolutionary eWindow Automotive Technology

Mativ (NYSE: MATV), a global leader in specialty materials innovation, has reached a landmark achievement in their strategic partnership with Miru Smart Technologies (“Miru”), a pioneering force in smart window technology. Through its advanced polymer film solutions brand, Argotec, Mativ has secured its first commercial purchase order for specialty materials used in Miru’s dynamic electrochromic window technology, obtained from a leading global glass manufacturer. This breakthrough not only solidifies Mativ’s position as a critical materials supplier for next-generation automotive smart glazing but also signals a major advance in readying the supply chain for large-scale production and worldwide adoption of electrochromic glass by prominent automotive original equipment manufacturers (OEMs).

This milestone aligns closely with Mativ’s long-standing commitments to innovation, sustainability, and safety — core values that underpin the company’s approach to developing cutting-edge specialty materials. As vehicle manufacturers and architects increasingly seek smart glazing solutions that improve energy efficiency, enhance occupant comfort, and elevate user experience, Mativ’s role as a materials partner for Miru positions the company at the forefront of an emerging smart glass revolution.

The Partnership: Mativ & Miru Driving Smart Glass Innovation

Miru Smart Technologies has garnered attention across the industry for its pioneering work in electrochromic (“EC”) window technology. EC glass enables windows and sunroofs to dynamically adjust their tint in response to user commands or environmental conditions, reducing glare, improving thermal management, and enhancing privacy. This transformative capability can significantly reduce the load on vehicle HVAC systems, lowering energy consumption and carbon emissions.

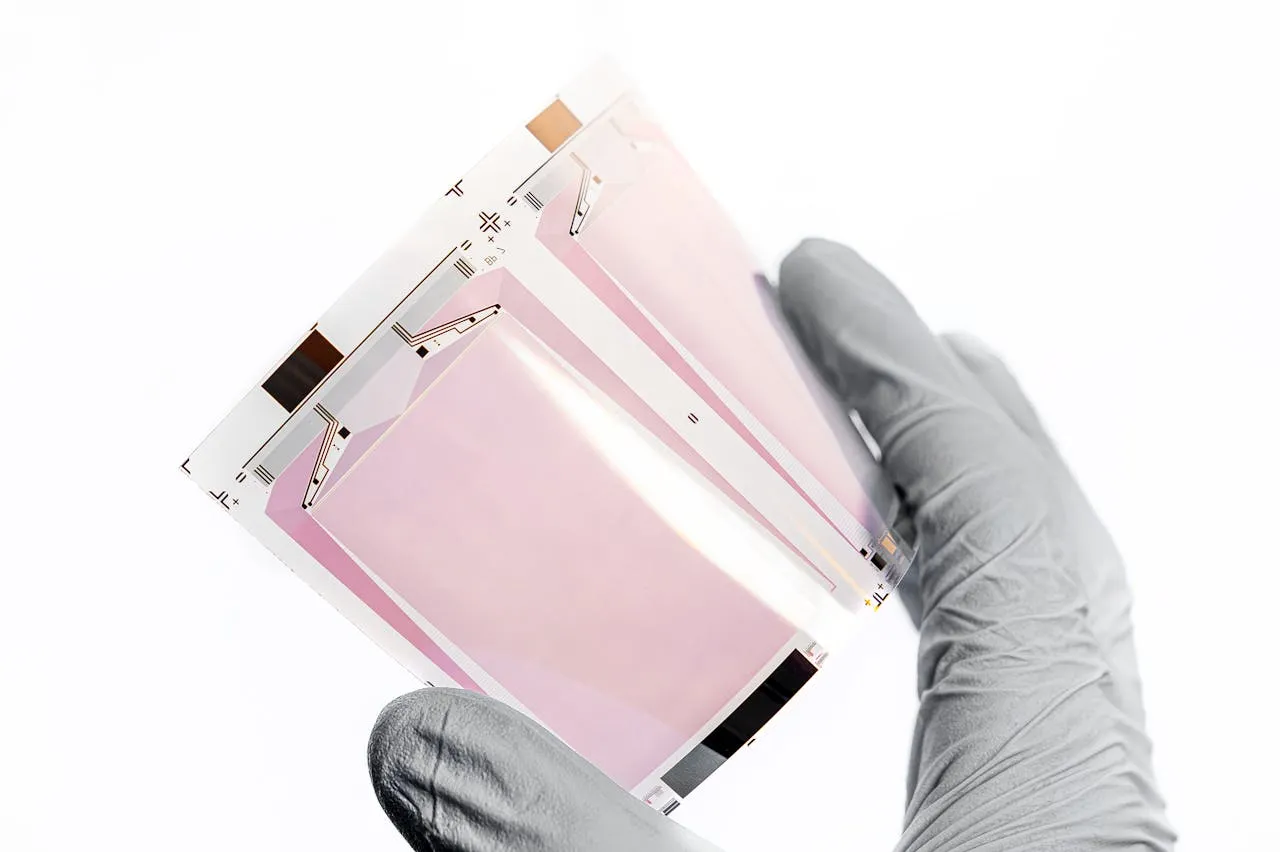

Central to this technology is the specialized polymer film developed and supplied by Mativ’s Argotec division. This film serves as a thermoplastic polyurethane (TPU) interlayer in Miru’s eWindow stack—a multilayer laminate comprising glass substrates and functional coatings. The TPU interlayer film not only facilitates electrochromic functionality but also ensures the finished window delivers optical clarity, mechanical durability, and manufacturability at scale.

Miru works closely with a network of major global glass manufacturers and supply chain partners to integrate this advanced TPU interlayer into dynamic eWindow assemblies. The close collaboration with Mativ has enabled extensive co-development, rigorous materials testing, and iterative refinements to meet demanding performance and quality standards required by automotive OEMs.

Breaking Ground with the First Commercial Purchase Order

The recent purchase order from a leading glass manufacturer represents Mativ’s first commercial supply agreement for the Argotec TPU film used in Miru’s eWindow technology. This order follows a period of comprehensive co-development and validation testing that confirmed the film’s ability to meet key optical, mechanical, and durability requirements under real-world conditions.

“This order reflects our confidence in the market demand for Miru’s exciting eWindow technology and our shared commitment to customer-driven innovation platforms,” said Ryan Elwart, Group President of Mativ. “Argotec’s advanced films are engineered specifically for the stringent performance needs of smart glazing applications, and we are proud to support Miru as they scale electrochromic glass for the future of mobility.”

The TPU film is a critical enabler of Miru’s eWindow systems, providing flexibility, resilience, and high optical quality needed for dynamic tinting. The robust film chemistry also facilitates manufacturing processes compatible with curved glass substrates, an increasingly important feature for modern vehicle design.

Demonstrating Scale and Capability: A Record-Setting Electrochromic Sunroof

A major highlight of the Mativ-Miru partnership was the successful fabrication of one of the world’s largest electrochromic sunroof prototypes. The component features a compound-curved shape measuring approximately 1.5 meters by 1.6 meters—dimensions that demonstrate the scalability of the technology beyond flat glass panes to complex, three-dimensional automotive surfaces.

This breakthrough prototype, enabled by Argotec’s TPU interlayer film, showcased the manufacturability and performance of Miru’s eWindow technology in realistic automotive conditions. The successful production of such a large, curved electrochromic device represents a pivotal step toward integrating dynamic smart glazing into premium vehicle models, where panoramic sunroofs and sophisticated light management features are increasingly sought after by consumers.

Curtis Berlinguette, Founder and CEO of Miru, remarked, “This announcement marks a major step forward in our supply chain readiness. Our partnership with Mativ ensures we have access to proven, scalable interlayer materials that meet the optical and mechanical performance standards of our eWindow system. We are excited to deepen this collaboration as we scale toward full production.”

The Growing Demand for Smart Glazing in Automotive and Architecture

The automotive industry is undergoing a rapid transformation driven by electrification, autonomous driving, and heightened consumer expectations for comfort and connectivity. Smart glazing solutions like Miru’s eWindows address several of these trends by improving energy efficiency, enhancing occupant comfort, and enabling new vehicle design possibilities.

Dynamic tinting capabilities reduce heat gain from solar radiation, helping electric vehicles extend their driving range by minimizing air conditioning load. Enhanced glare control improves safety and visual comfort, while the ability to switch window opacity on demand adds privacy and style options.

Beyond automotive applications, Miru’s eWindow technology has strong potential in architectural markets. Electrochromic glass can dynamically regulate natural light and heat in building facades and skylights, contributing to sustainable building designs that reduce energy consumption and improve occupant wellbeing.

Mativ’s Role as a Materials Innovator in the Smart Glass Ecosystem

Mativ’s Argotec brand brings decades of expertise in specialty polymer films, delivering advanced materials engineered to meet demanding performance, quality, and sustainability criteria. The TPU interlayer film supplied for Miru’s eWindows is designed for optical clarity, dimensional stability, and compatibility with the multilayer laminate process used in automotive glass manufacturing.

The company’s materials innovation extends beyond performance to encompass environmental and safety considerations. TPU interlayers offer improved durability and longevity compared to conventional materials, reducing replacement cycles and waste. Furthermore, the chemistry can be tailored to support recyclability and align with circular economy principles, a growing priority among automotive OEMs and glass manufacturers.

Mativ’s partnership with Miru underscores its commitment to collaborating closely with technology innovators and manufacturers across the value chain to accelerate the adoption of smart materials that drive industry transformation.

Industry Recognition and Future Outlook

The momentum behind Miru’s eWindow technology and Mativ’s Argotec materials was recently on full display ahead of Glass Performance Days (GPD) 2025, an influential global glass industry event held in Tampere, Finland. Both companies showcased their joint solution in a dedicated booth, providing attendees a firsthand look at the dynamic tinting capabilities and scalable production technologies underpinning Miru’s eWindows.

In addition to the exhibition, Mativ and Miru hosted a networking mixer at GPD 2025, bringing together industry leaders, innovators, and customers to explore the future of smart glass and dynamic glazing systems.

Looking ahead, both Mativ and Miru anticipate continued growth fueled by expanding demand from automotive OEMs incorporating advanced smart glazing features in their vehicle portfolios. The companies are focused on scaling manufacturing capacity, further refining materials and system performance, and expanding into architectural applications to capture broader market opportunities.

Mativ’s first commercial order for Argotec specialty TPU interlayer film marks a significant milestone in the evolution of smart window technology. The partnership with Miru Smart Technologies exemplifies how collaborative innovation and advanced materials engineering can unlock new possibilities for dynamic, sustainable, and high-performance glazing solutions in automotive and architectural markets.

As the global push for energy efficiency, occupant comfort, and innovative design intensifies, the combined strengths of Mativ and Miru are well-positioned to accelerate the adoption of electrochromic glass technologies worldwide. This achievement highlights not only the technical and commercial viability of dynamic smart windows but also the critical role that advanced specialty materials play in driving next-generation mobility and building solutions.

With commercial production now on the horizon and robust industry interest building, Mativ and Miru are ushering in a new era where windows do more than just provide transparency—they become intelligent interfaces enhancing the way we interact with our environment.