Forged Composite Market: Analysis, Trends, and Forecast (2024-2030)

The global forged composite market is poised for significant growth, expected to expand at a compound annual growth rate (CAGR) of 6% from 2025 to 2030. This growth is being driven by increasing demand across various industries for lightweight, high-strength materials, which are crucial for improving performance while reducing weight in applications ranging from automotive to aerospace.

The report titled, “Forged Composite Market: Market Size, Trends, Opportunities, and Forecast by Resin Type, Application, Fiber Type, Region, By Country: 2020-2030”, offers a comprehensive view of the market’s trajectory, examining factors influencing market expansion and identifying key trends and growth opportunities.

Introduction to Forged Composites

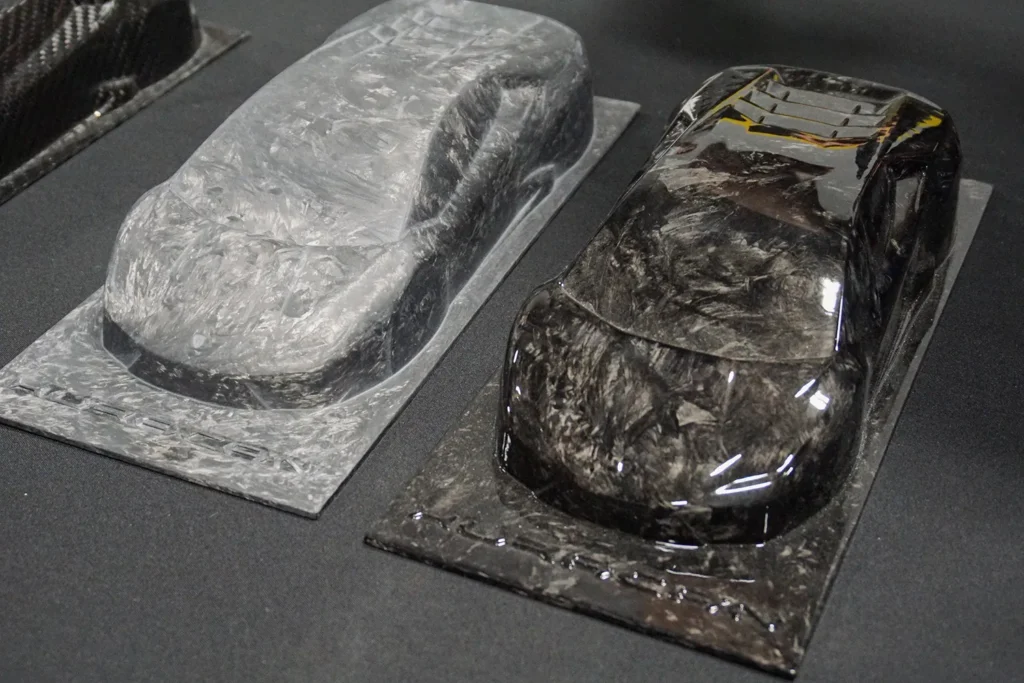

Forged composites are a cutting-edge class of materials composed by compressing carbon fiber with resin in a mold. This process results in components that are significantly lighter and more durable than traditional materials like metals. The resulting forged composite materials combine rigidity, strength, and lightness—qualities that make them ideal for industries that prioritize performance and weight efficiency.

Market Drivers and Growth Factors

- Automotive Industry: The automotive sector is one of the largest consumers of forged composites. As automotive manufacturers strive to reduce vehicle weight, they increasingly turn to forged composites to improve fuel efficiency and meet stringent emission standards. These materials are extensively used in vehicle body panels, chassis, and interior components. Furthermore, with the rise in electric vehicle (EV) production, the demand for lightweight materials is even greater, as EV manufacturers seek to improve battery range and enhance overall efficiency. Forged composites help optimize structural design without compromising vehicle safety or performance.

- Aerospace Sector: The aerospace industry has also embraced forged composites to reduce the overall weight of aircraft, which in turn improves fuel efficiency and lowers operating costs. Components made from forged composites are designed to withstand the harsh conditions of flight, including high stress and extreme temperatures, making them indispensable in the production of both military and commercial aircraft.

- Sports and Consumer Goods: The demand for high-performance sporting equipment has boosted the use of forged composites in products such as golf clubs, tennis rackets, and bicycles. These materials offer a unique combination of strength and lightweight properties that improve the performance of sports equipment. Additionally, consumer goods manufacturers are exploring forged composites for their ability to provide durability while minimizing weight.

Forged Composite Market Segmentation

- By Resin Type:

- Epoxy: Widely used due to its excellent adhesive properties and high mechanical strength.

- Polyester: Known for its cost-effectiveness and high-performance characteristics in many industrial applications.

- Thermoplastic: Offers enhanced toughness and flexibility, suitable for a wide range of applications.

- Polyurethane: Offers high durability and flexibility.

- Other Resin Types: Including various specialized resins used in niche applications.

- By Application:

- Automotive & Transportation: This sector remains the largest driver, as it accounts for nearly 40% of the total forged composite market share in 2023.

- Sporting Goods: This segment is also witnessing substantial growth, driven by the demand for high-quality equipment.

- Aerospace & Defense: Forged composites are critical in reducing the weight of aircraft while maintaining strength and resilience in extreme environments.

- Other Applications: Includes uses in consumer goods and industrial products.

- By Fiber Type:

- Glass Fiber: Offers good strength and is generally more affordable than carbon fiber, making it ideal for budget-conscious applications.

- Carbon Fiber: Known for its superior strength-to-weight ratio, carbon fiber is a preferred choice in high-performance industries such as aerospace and automotive.

Regional Insights

- Americas: The Americas dominate the global forged composite market, driven by robust automotive and aerospace industries. North America, in particular, is a leader in the production and consumption of forged composites due to the high demand for lightweight materials in EVs and fuel-efficient aircraft. The region is expected to continue growing as manufacturers increasingly prioritize sustainability and efficiency.

- Asia Pacific: The Asia Pacific region is experiencing rapid growth due to expanding automotive manufacturing, especially in countries like China, Japan, and South Korea. Additionally, the increasing demand for consumer goods in emerging markets is driving the adoption of forged composites in products across various sectors.

- Europe: Europe is also a significant player in the market, with Germany, France, and the United Kingdom being key contributors. The continent is home to leading automotive and aerospace companies, contributing to the demand for advanced composite materials. Moreover, Europe’s focus on reducing emissions has driven innovations in lightweight materials for both automotive and aviation sectors.

- Middle East and Africa (MEA): The MEA region represents a smaller share of the market but is witnessing growing interest in forged composites, particularly within the aerospace and automotive industries, as countries seek to modernize their infrastructure and improve fuel efficiency.

Competitive Landscape

The forged composite market is characterized by a high degree of competition, with numerous players actively involved in product development, mergers, acquisitions, and strategic collaborations. The top companies in this space include:

- Innovative Composite Engineering Inc.

- Callaway Golf

- Mansory Design & Holding GmbH

- Forged Carbon (Tecalemit Group)

- Real Carbon Inc.

- Bulgari

- Action Composites

- Modern Composites Ltd.

These companies are striving to maintain a competitive edge by focusing on research and development to innovate new products and enhance material properties.

Key Factors to Watch in the Forged Composite Market

- Technological Advancements: Ongoing research is expected to further improve the manufacturing processes and properties of forged composites. Innovations in resin formulations and fiber technologies could lead to the development of even lighter and stronger materials.

- Sustainability and Environmental Impact: The growing focus on sustainability is pushing industries to consider the lifecycle impact of materials. Forged composites, known for their durability and lightweight nature, present a sustainable option for manufacturers seeking to reduce emissions and improve energy efficiency.

- Market Consolidation: Mergers, acquisitions, and collaborations are likely to continue as companies seek to expand their product portfolios and reach new geographical markets. Strategic alliances between key players in automotive, aerospace, and sports goods are expected to drive the evolution of the market.

- Government Regulations and Standards: The implementation of stricter emissions regulations, especially in the automotive and aerospace industries, is likely to continue supporting the demand for lightweight materials like forged composites.

Market Outlook and Forecast (2025-2030)

The forged composite market is set for sustained growth from 2025 to 2030. As industries such as automotive and aerospace continue to prioritize lightweight materials for efficiency and performance, demand for forged composites will increase. The trend toward electric vehicles and the ongoing quest for fuel-efficient aircraft will further fuel market expansion.

The sports industry’s increasing use of advanced composites in high-performance goods is also expected to contribute to the overall market size. As companies across different sectors continue to explore and adopt forged composites, the market will witness new applications and innovations, driving continued growth through the decade.

The forged composite market is experiencing a period of expansion driven by the demand for lightweight, high-strength materials across key industries. With applications in automotive, aerospace, and sports goods, the market is witnessing an upward trajectory, fueled by advancements in materials technology and manufacturing processes. As we move toward 2030, the market is expected to grow at a steady pace, with North America and Asia Pacific leading the charge in terms of consumption and innovation.

To make informed decisions, companies should focus on emerging trends, technological advancements, and key market players. The upcoming years promise exciting developments and opportunities within this dynamic market.