Argonne Scientists Explore 3D-Printed Steels for Future Nuclear Reactors

Stainless steel has been a cornerstone of the nuclear power industry for decades. Known for its durability and resistance to heat, pressure, and radiation, it has been used to fortify reactor walls and form essential components that must survive extreme operating conditions over long lifetimes. But as the industry looks toward next-generation nuclear reactors, researchers are exploring whether steels produced through 3D printing technologies can meet — or even exceed — the high standards set by traditional wrought materials.

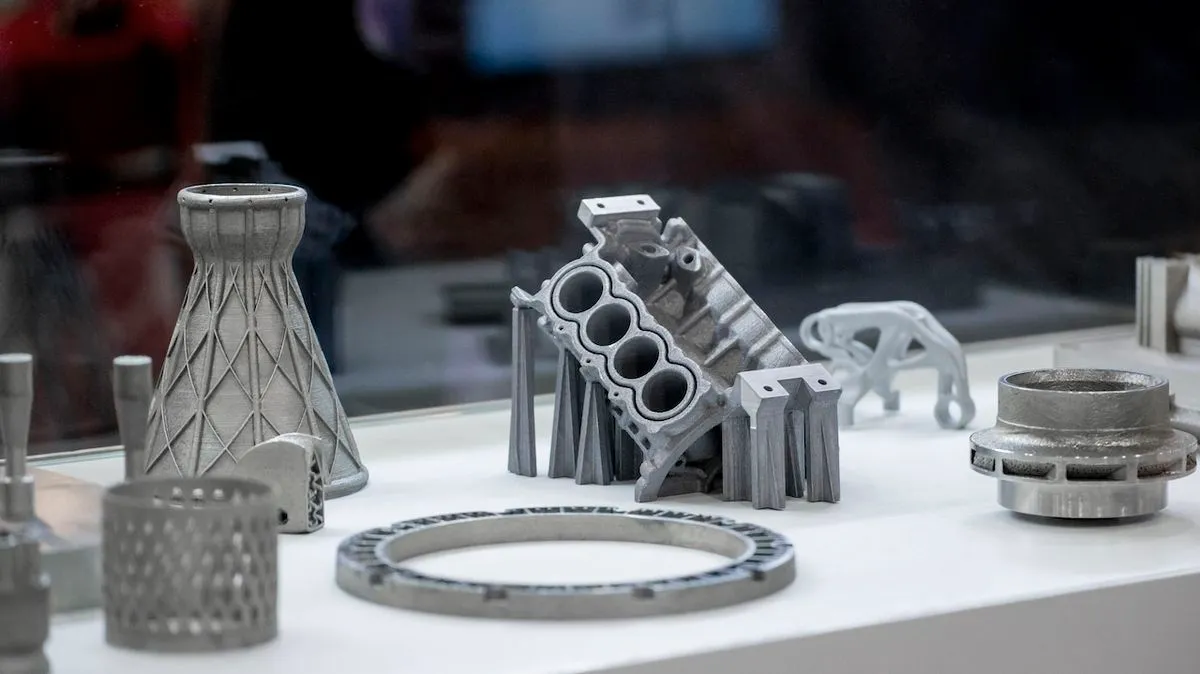

The potential advantages of additive manufacturing, often called 3D printing, are significant. Components can be produced more quickly, customized to specific reactor designs, and manufactured with complex geometries that are difficult or impossible to achieve with conventional methods. However, before these new steels can be adopted in nuclear environments, industry leaders and scientists need a much deeper understanding of how they behave under real-world conditions.

That challenge is at the center of recent work conducted by the U.S. Department of Energy’s (DOE) Argonne National Laboratory. In two complementary studies, Argonne researchers examined stainless steels produced using laser powder bed fusion (LPBF), one of the most widely used additive manufacturing techniques.

Understanding Laser Powder Bed Fusion

In LPBF, a laser beam fuses metal powders layer by layer, following a digital design to create a fully solid object. Each pass of the laser rapidly heats and cools the powder, producing microstructural features that differ significantly from those found in wrought steels. While these unique features can create opportunities to enhance material properties, they can also introduce uncertainties about performance in high-stakes environments such as nuclear reactors.

One of the key concerns is how the steels respond to heat treatment after printing. During this process, a material undergoes recovery, where elevated temperatures allow atoms to rearrange and reduce internal stresses. In some cases, this recovery continues into recrystallization, which replaces the strained microstructure with new, defect-free grains. Yet, not all defects are bad. Retaining some dislocations can actually benefit performance, as they promote the formation of small particles, called precipitates, that strengthen the material.

Study One: Printed 316H Steel

The first Argonne study examined 316H stainless steel, a widely used material in its wrought form that has long served the nuclear industry. The research team produced LPBF samples of 316H and investigated their structures using X-ray diffraction and electron microscopy.

These high-resolution techniques, carried out at Argonne’s Center for Nanoscale Materials (CNM) and the Advanced Photon Source (APS) — both DOE Office of Science user facilities — allowed researchers to observe the fine details of the steel’s internal structure. They then connected this structural data to key mechanical properties such as tensile strength and creep resistance.

Creep, in particular, is a critical property for nuclear materials. It refers to the slow, permanent deformation of a material under constant mechanical stress, especially at high temperatures. Over years of reactor operation, creep can compromise component integrity if not carefully managed. By studying how printed 316H responds to heat treatment and long-term stress, the Argonne team provided valuable insights for future reactor designers considering additive manufacturing.

Study Two: Printed A709 Steel

In their second study, the researchers turned their attention to A709 stainless steel, a more advanced alloy developed specifically for high-temperature applications such as sodium fast reactors. For the first time, Argonne scientists produced and studied A709 using LPBF, comparing the printed samples with traditional wrought versions of the alloy.

After subjecting the printed A709 to heat treatment, the team tested its performance under tension at both room temperature and 1,022°F (550°C) — a temperature highly relevant to next-generation sodium fast reactors. Remarkably, the printed samples showed higher tensile strength than their wrought counterparts across both conditions.

The researchers attributed this improvement to the higher density of dislocations present in the printed material. These dislocations facilitated the formation of more precipitates during heat treatment, further enhancing strength. The results suggest that 3D printing could not only match but also improve upon the performance of certain steels when carefully processed.

A Step Toward Practical Applications

“Our research is providing practical recommendations for how to treat these alloys,” explained Xuan Zhang, materials scientist at Argonne and co-author of both studies. “But I believe our biggest contribution is a greater fundamental understanding of printed steels.”

This deeper understanding will be crucial as the nuclear industry evaluates whether to incorporate 3D-printed components into reactor systems. Beyond simply proving that additive manufacturing works, scientists must demonstrate consistent reliability, long-term stability, and resilience to radiation — all under the demanding conditions that reactors impose.

The Argonne studies represent a significant step forward, highlighting both opportunities and challenges. While much research remains to be done, particularly around irradiation effects and large-scale manufacturing feasibility, the early results are promising. By combining advanced materials science tools with innovative manufacturing techniques, Argonne researchers are helping to pave the way for safer, more efficient, and more adaptable nuclear technologies in the decades ahead.