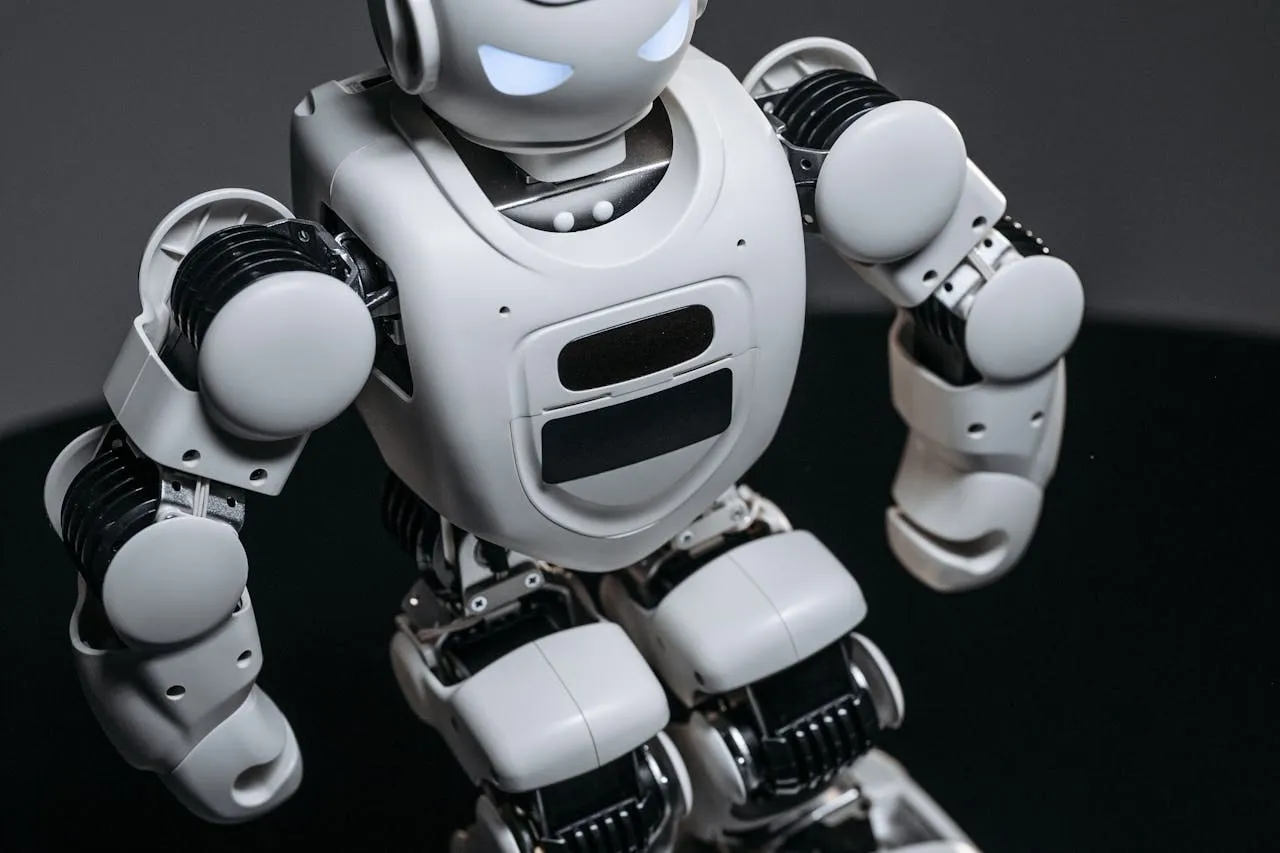

Agility Robotics Unveils New Innovations for Humanoid Robot Digit

Agility Robotics, the creator of the humanoid robot Digit, has introduced a suite of new capabilities and advancements designed to extend the robot’s utility and meet the increasing demands of its growing customer base. These innovations were revealed at ProMat, a premier event for the manufacturing and supply chain industries. Created through close collaboration with customers, these new features facilitate the rapid and scalable deployment of Digit fleets, enabling them to perform a broader range of tasks with greater efficiency. Among the key advancements are:

- Improved battery capabilities, extending operational time to up to four hours with enhanced energy efficiency.

- Autonomous docking to charging stations, ensuring that Digit can recharge without human intervention.

- Streamlined manufacturing processes to accelerate production.

- Enhanced safety features, including a Category 1 (CAT1) stop, a Safety PLC, an on-robot emergency stop (E-stop), a wireless teach pendant with integrated E-stop, and Functional Safety over EtherCAT (FSoE).

- New, more durable limbs and end effectors that expand Digit’s ability to manipulate objects with a wider range of grasping angles, enabling new use cases.

Melonee Wise, Chief Product Officer at Agility Robotics, emphasized that these upgrades allow the company to meet its expanding commercial needs. “Together, these innovations reinforce our commitment to cooperative safety and lay the groundwork for future human-robot collaboration,” she said.

The road to widespread adoption of humanoid robots is paved by real-world deployments, and Agility Robotics is at the forefront of this effort. The company is the only one with a commercially-deployed humanoid robot, Digit, working in warehouses and manufacturing environments. This unique position allows Agility to engage directly with customers, test new functionalities, deploy robots, build relevant skills, and measure the robots’ true value in operational settings.

AMR Integration

A key aspect of Digit’s design is its ability to work in tandem with Autonomous Mobile Robots (AMRs). Rather than replacing AMRs, humanoids like Digit are designed to complement them. Humanoids excel in complex manipulation and can navigate human-centric spaces, while AMRs are specialized in efficient transportation over longer distances. This complementary dynamic allows Digit to autonomously dispatch AMRs to deliver items to new locations, such as packout stations, reducing the need for human intervention. This collaboration enhances the overall efficiency of operations by enabling workers to focus on more intricate tasks while leveraging automation to manage repetitive, manual work.

While AMRs have become a fast-adopted solution in warehouses and manufacturing settings, their widespread deployment has created “islands of automation.” The integration of humanoids into existing systems is becoming increasingly important. Digit is currently integrating with leading AMR companies, and Agility’s Arc cloud robotic platform enables seamless communication and coordination between robots and AMRs. The Arc platform allows Digit to work alongside AMRs, calling and dispatching them to tasks as needed. In a notable example, Digit has been deployed alongside MiR and Zebra Technologies’ AMRs at a facility operated by GXO near Atlanta, Georgia. The successful integration of these robots was also showcased at the ProMat trade show in Chicago.

Advancing Safety Standards

While there are established safety standards for industrial machines and robots, safety protocols specifically for Dynamically Stable Industrial Mobile Robots (DSIMRs) like Digit are still in development. These robots require stability and balancing capabilities that present unique safety challenges. Agility Robotics is pushing the envelope on safety by ensuring that its humanoid robots meet the rigorous safety standards necessary for operation in OSHA-regulated environments, where robots may need to work alongside human workers.

The latest version of Digit includes several new safety features that address these challenges. These features represent significant steps toward establishing cooperative safety standards for humanoid robots:

- Category 1 (CAT1) Stop: This feature maintains power to the machine actuators during the deceleration process, ensuring that the robot stops smoothly and safely before power is completely removed.

- Safety PLC (Programmable Logic Controller): This component is used to provide safety functions that meet performance level d (PLd) standards, ensuring that the robot operates safely in various environments.

- Emergency Stop (E-stop): Digit is equipped with an E-stop button, which can immediately halt all movements in the event of an emergency. This feature is essential for preventing accidents and ensuring worker safety.

- Functional Safety over EtherCAT (FSoE): FSoE ensures the safe communication of critical data, such as emergency stop signals and sensor feedback, across an EtherCAT network, while maintaining real-time performance.

These features, combined with continuous compliance with multiple safety standards, demonstrate Agility Robotics commitment to safety and its efforts to make humanoid Agility Robotics more cooperative with human workers in industrial environments.

Agility Arc: The Cloud-Based Fleet Management System

Agility’s Arc platform is a cloud-based robotic automation system that gives customers complete control over their fleet of robots and automated equipment. Arc facilitates the deployment and integration of automated workflows into logistics and manufacturing operations, making it the first humanoid fleet management system to be deployed commercially. One of the key updates to the Arc platform is its integration with AMRs, allowing customers to deploy and communicate with AMRs alongside humanoid robots.

Other new features of the Arc platform include:

- Digit Support: Arc now offers dedicated support for Digit, making it easier for customers to manage and deploy humanoid robots.

- Charger Support: Integration with chargers ensures that the fleet of robots can autonomously recharge when needed.

- Workcell EMS Support: Enhanced support for workcell management systems ensures seamless integration of robots into various work environments.

- Webhook Integration: Arc now supports easy webhook integration, enabling users to connect to other systems and workflows.

- Remote Monitoring and Support: Customers can remotely monitor and maintain their Digit robots and accessories.

- Expanded Enterprise Systems Integration: Arc supports integration with enterprise systems such as MES (Manufacturing Execution Systems), WMS (Warehouse Management Systems), WES (Warehouse Execution Systems), and PLCs (Programmable Logic Controllers).

These new features further expand the capabilities of Agility Arc, allowing businesses to seamlessly integrate humanoid Agility Robotics into their operations, enhancing productivity and operational efficiency.

New Use Cases for Digit

During the ProMat show, Agility Robotics also demonstrated new use cases for Digit, highlighting the robot’s flexibility and potential for future applications. Some of the new use cases on display included:

- AMR Integration: Digit’s ability to work alongside AMRs for efficient transportation and delivery.

- Tote Stacking and Unstacking: Digit demonstrated the ability to stack and unstack totes, a common task in warehousing.

- Unit Sorter and G2P (Goods-to-Person): Digit can be integrated into unit sortation systems or G2P workflows to improve operational efficiency.

- AMR Loading and Unloading: Digit can autonomously load and unload AMRs, further streamlining operations.

- Palletizing and Depalletizing: Digit’s enhanced grasping and manipulation capabilities allow it to efficiently manage palletizing and depalletizing tasks.

- Nesting, Flowrack, and Carts: Digit can handle nesting and manage flowrack systems and carts to support various warehouse processes.

- Automated Putwall: Digit demonstrated the ability to work with automated putwalls, sorting and placing items into designated locations.

These Agility Robotics demonstrations underscore the wide range of potential applications for humanoid robots in logistics, warehousing, and manufacturing. The Agility Robotics advancements in Digit’s capabilities are a testament to the growing role that humanoid robots are playing in transforming industrial operations.

Agility Robotics With these continued innovations, Agility Robotics is solidifying its position as a leader in the humanoid robotics space, ensuring that Digit remains at the forefront of industrial automation. The combination of safety enhancements, AMR integration, and expanded capabilities positions Digit as an essential tool for businesses seeking to optimize their operations in the ever-evolving landscape of modern manufacturing and logistics.