Aerospace Tubes Market Outlook 2025–2032: Size, Share, Trends, and Growth Forecast

The report titled “Aerospace Tubes Market Size, Share, Trends, Dynamics, Forecast, & Growth Analysis: 2025–2032” has been added to the offerings of ResearchAndMarkets.com. The study provides an in-depth assessment of the global aerospace tubes market, highlighting its growth outlook, competitive landscape, and evolving technological trends over the forecast period.

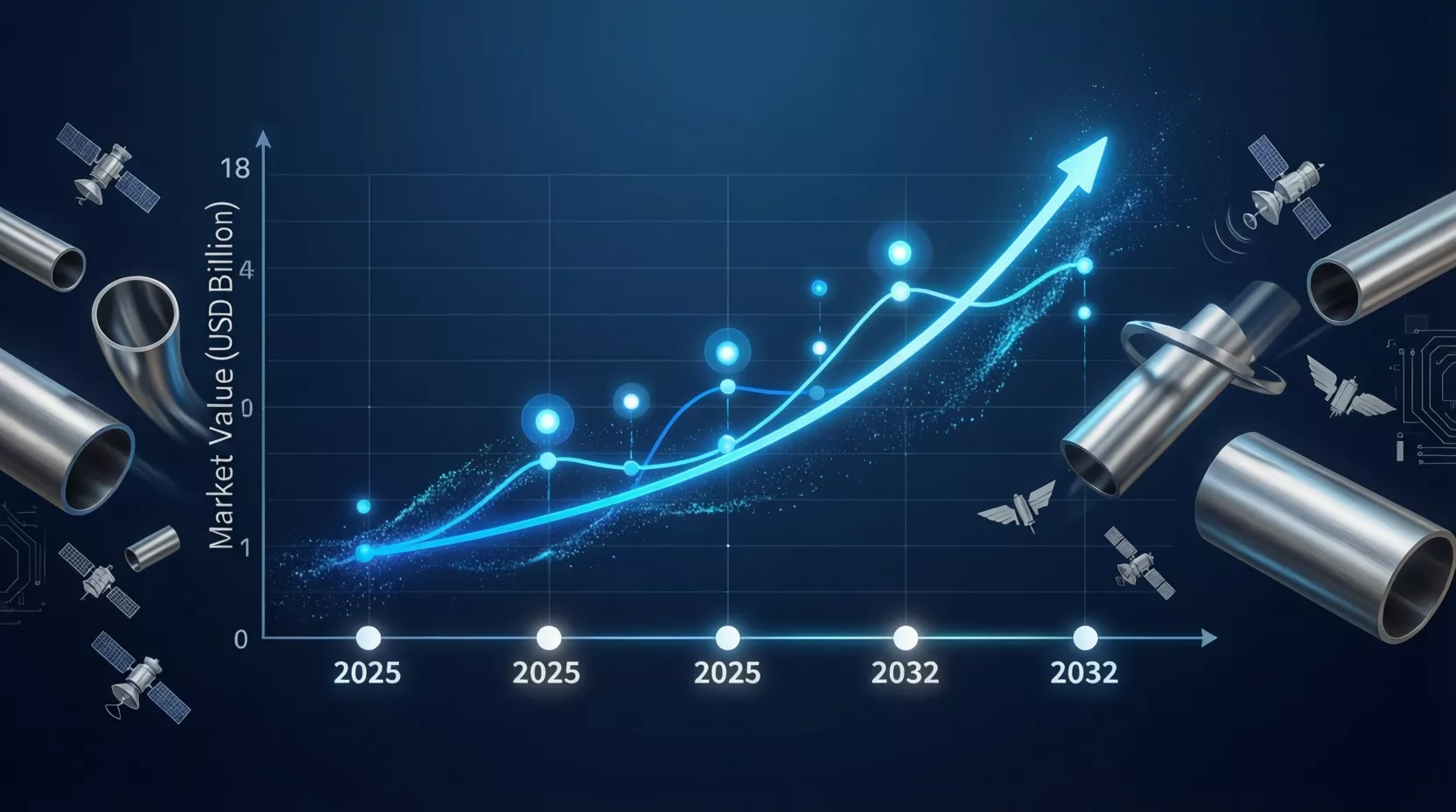

The aerospace tubes market is expected to follow a steady growth path, expanding from an estimated value of USD 726 million in 2024 to approximately USD 1 billion by 2032, representing a compound annual growth rate (CAGR) of 3.8%. This growth is supported by the continued expansion of the global aerospace sector, rising demand for fuel-efficient aircraft, and a growing emphasis on lightweight, durable, and high-performance components across both commercial and defense aviation platforms.

Technological advancements in materials science and manufacturing processes are playing a pivotal role in shaping the market. Innovations are enabling the production of aerospace tubes that improve aircraft safety, operational efficiency, and service life. At the same time, increasing aircraft production rates and ongoing fleet modernization programs are generating sustained demand for advanced tubing solutions across new builds as well as replacement and maintenance cycles.

The market remains moderately concentrated, with several established players holding significant market shares. Key companies operating in this space include Arconic Corporation, Alleima (Sandvik), Ametek Inc., Constellium SE, and VSMPO-AVISMA Corporation, all of which benefit from strong manufacturing capabilities, long-term OEM relationships, and advanced material expertise.

From a segmentation perspective, commercial aircraft represent the largest platform segment, driven by high-volume programs such as the Airbus A320neo and Boeing 737 MAX, both of which require extensive tubing assemblies. Long-term growth is further supported by projections indicating a doubling of global air traffic by 2040, which will drive both initial installations and aftermarket replacement demand.

By function type, hydraulic and instrumentation lines account for the largest share of the market due to their critical role in essential aircraft systems such as landing gear, braking, and flight controls. Meanwhile, bleed lines are expected to register the fastest growth rate, supported by the adoption of advanced environmental control systems and the shift toward more-electric aircraft architectures.

In terms of application, airframe-related uses dominate the market, as aerospace tubes are required across a wide range of structural and fluid distribution systems. Engine applications, however, are forecast to grow at a faster pace, reflecting increased demand for next-generation propulsion systems and improved thermal and pressure management solutions.

By product type, seamless tubes continue to be the preferred choice due to their superior strength, reliability, and ability to withstand extreme pressure and temperature conditions. These characteristics make them especially suitable for high-stress aerospace applications. From a material standpoint, titanium alloys are the most attractive option, offering an optimal balance of strength, corrosion resistance, and weight reduction—key factors in improving fuel efficiency and aircraft performance.

With respect to sales channels, indirect sales remain dominant, reflecting the tiered structure of the aerospace supply chain. This approach allows manufacturers to meet strict certification requirements while maintaining traceability and compliance with aerospace quality standards.

Regionally, North America holds the largest share of the global aerospace tubes market, supported by the presence of major aircraft OEMs such as Boeing, a strong maintenance, repair, and overhaul (MRO) ecosystem, and sustained defense spending. Asia-Pacific is expected to be the fastest-growing region, driven by rapid growth in air travel, expanding aerospace manufacturing capabilities, and rising investments in indigenous aircraft programs. Initiatives such as COMAC’s C919 in China and India’s AMCA program are expected to significantly boost regional demand for advanced aerospace tubing systems.

Recent mergers, acquisitions, and strategic transactions have further shaped the competitive landscape. In 2024, Acerinox, through its subsidiary North American Stainless, acquired Haynes International, strengthening its position in aerospace materials. In 2025, Leggett & Platt agreed to sell its Aerospace Products Group to Tinicum Incorporated for USD 285 million, highlighting ongoing portfolio optimization across the industry.

The report covers a wide range of analytical areas, including market environment assessment, supply chain analysis, PEST analysis, industry life cycle evaluation, and detailed segmentation by aircraft type, function, application, product, material, sales channel, and region. It also includes competitive benchmarking, market share analysis, Porter’s Five Forces assessment, and identification of strategic growth opportunities.

Company profiles featured in the report include Alleima (Sandvik), Ametek Inc., Constellium SE, Haynes International (acquired by Acerinox), Kaiser Aluminum Corporation, Leggett & Platt, Plymouth Tube Company, Senior plc, and VSMPO-AVISMA Corporation, offering detailed insights into their strategies, product portfolios, and market positioning.

Source link: https://www.businesswire.com/