Siemens to Invest Over $10 Billion in U.S. Manufacturing, Software, and AI Infrastructure

Siemens, a global technology powerhouse, is ramping up its investments in the United States to strengthen the country’s industrial technology sector and expand its role in the rapidly evolving AI and manufacturing industries. With a strong commitment to American talent and supply chains, Siemens is poised to support the next phase of the U.S. industrial renaissance through advanced manufacturing, software innovations, and AI-powered solutions.

Roland Busch, President and CEO of Siemens AG, emphasized the significance of the move, stating, “The industrial tech sector is the foundation for boosting manufacturing in America, and Siemens is in a unique position to drive this transformation. From small and medium-sized enterprises to industrial giants, our investments will help customers navigate and thrive in this new era of industrial technology.”

A Major Investment in U.S. Manufacturing

Currently, the United States is Siemens’ largest market, and the company has consistently relied on American talent and supply chains to drive its growth. With its latest investments, Siemens is further cementing its footprint in the country’s manufacturing sector. The company’s commitment of over $10 billion includes a series of strategic acquisitions, facility expansions, and technological advancements.

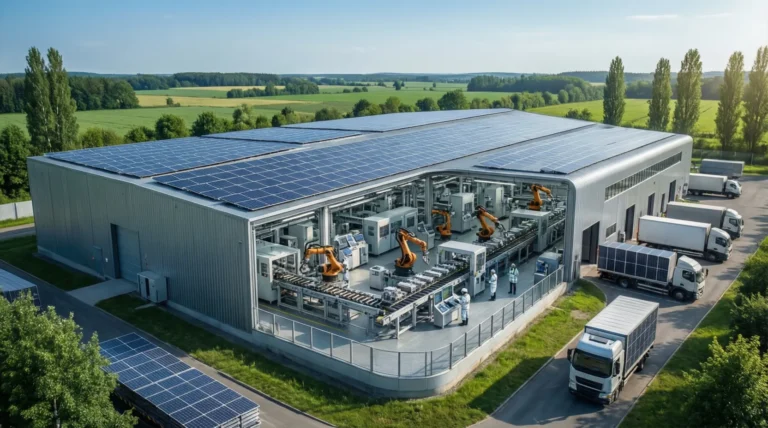

As part of this effort, Siemens is unveiling two state-of-the-art manufacturing facilities in Fort Worth, Texas, and Pomona, California. These new plants, representing an investment of $285 million, are expected to create over 900 high-skilled manufacturing jobs.

The Fort Worth and Pomona facilities will focus on the production of cutting-edge electrical equipment that will serve crucial sectors, including commercial, industrial, and construction markets. In addition to enhancing these industries, the newly manufactured equipment will play a pivotal role in supporting AI data centers across the country, solidifying the U.S.’s position as a leader in industrial AI advancements.

By expanding its manufacturing capabilities, Siemens is doubling its production capacity of essential electric equipment needed to power America’s critical infrastructure, including AI-driven data centers. These centers, which rely on high-efficiency power solutions, are at the forefront of digital transformation, artificial intelligence, and automation, making Siemens’ investment a key enabler of U.S. industrial and technological progress.

Advancing AI-Powered Software Solutions

Beyond manufacturing, Siemens is doubling down on AI-powered software to revolutionize product design and industrial processes in the U.S. A significant step in this direction is its planned acquisition of Altair, a Michigan-based software company known for its expertise in simulation and design optimization. The deal, expected to be completed in late 2024, will allow Siemens to further integrate AI-driven capabilities into its existing software suite.

By merging Altair’s technology with Siemens’ extensive portfolio, the company aims to offer the world’s most comprehensive AI-powered design and simulation tools. These solutions will enable engineers and manufacturers to create more complex and intelligent products with greater efficiency. Through digital simulation, companies will be able to conduct virtual crash tests for automotive designs, predict the structural durability of new materials, and optimize the performance of consumer electronics before physical prototypes are built. AI-powered modeling and analytics will further accelerate product development, reduce costs, and improve overall design quality.

This enhanced software suite will allow industries across the U.S. to move towards a more agile, digital-first manufacturing approach, boosting competitiveness on a global scale. The combination of AI, digital simulation, and real-world data analytics will help businesses optimize production workflows, reduce waste, and enhance product safety—key factors in building the next generation of industrial innovation.

Strengthening Siemens’ U.S. Presence

Siemens has been an integral part of the U.S. economy for decades. Over the past 20 years, the company has invested more than $90 billion in the country, spanning various industries, including manufacturing, infrastructure, mobility, and healthcare. With this year’s additional investments, Siemens’ total financial commitment in the U.S. will surpass $100 billion.

“We believe in the innovation and strength of America’s industry. Our continued investments underscore our confidence in the country’s ability to lead in the areas of manufacturing, artificial intelligence, and digital transformation. We are bringing more jobs, more technology, and a boost to America’s AI capabilities,” said Roland Busch.

Currently, Siemens employs more than 45,000 people in the U.S., working across a diverse range of industries. Additionally, the company partners with approximately 12,000 suppliers nationwide, further reinforcing its deep integration within the American industrial ecosystem.

Siemens’ Role in Sustainable and Smart Manufacturing

One of Siemens’ key strategic focuses is the intersection of digitalization and sustainability. Through smart manufacturing solutions, the company is helping businesses transition to more efficient, environmentally friendly production processes.

The new Fort Worth and Pomona facilities will incorporate Siemens’ own smart factory solutions, integrating automation, real-time data analytics, and digital twin technology to optimize production efficiency and minimize waste. These factories are designed to be highly energy-efficient, reducing emissions while maximizing output—a crucial factor in advancing sustainable industrial operations.

Furthermore, Siemens’ AI-driven software will play a pivotal role in designing greener products, from electric vehicles to smart grids. By enabling industries to create optimized designs and minimize material usage, Siemens is contributing to the overall reduction of carbon footprints in multiple sectors.

A Commitment to U.S. Industrial Leadership

With its latest investments, Siemens is positioning itself as a cornerstone of the U.S. industrial and technological ecosystem. From strengthening manufacturing capabilities to pioneering AI-powered software solutions, the company’s initiatives are set to accelerate America’s leadership in industrial innovation.

Siemens’ efforts align with the broader push towards Industry 4.0, where automation, AI, and digitalization are transforming traditional industries. By integrating these technologies, U.S. businesses can improve efficiency, reduce operational costs, and maintain a competitive edge in the global market.

The company’s ongoing commitment to investing in American infrastructure, workforce development, and supply chains underscores its belief in the future of U.S. manufacturing. As the world transitions into an era dominated by digital and AI-driven solutions, Siemens is ensuring that the U.S. remains at the forefront of these advancements.

Siemens’ $10 billion investment in the U.S. represents a bold step towards shaping the future of American manufacturing and technology. Through strategic acquisitions, cutting-edge software development, and large-scale manufacturing expansions, the company is reinforcing its leadership in the industrial sector.

As continues to drive innovation in AI, automation, and digital transformation, its impact on U.S. industries will be profound. With a focus on sustainability, efficiency, and workforce development, the company is not only contributing to economic growth but also paving the way for a smarter, more resilient industrial future.