First AMCM M290-2 FLX with nLIGHT in North America Delivered to Sintavia

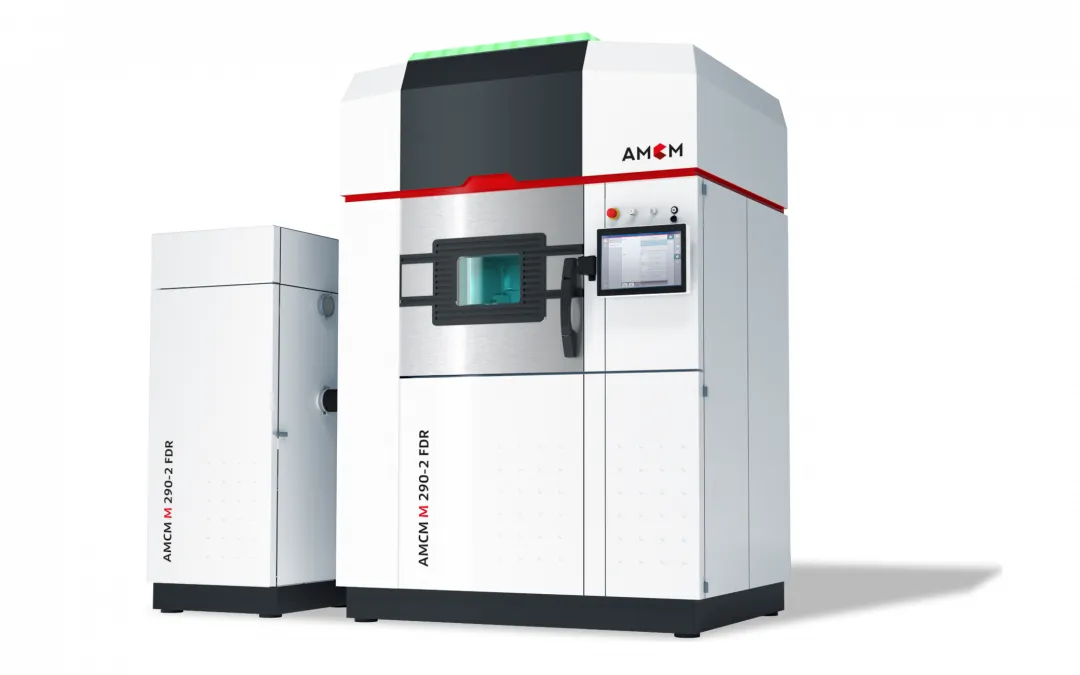

Sintavia, LLC, a trailblazer in the world of all-digital aerospace component manufacturing, has announced the commissioning of North America’s first multi-laser industrial 3D printer featuring nLIGHT AFX beam shaping fiber laser technology. This significant development marks a major leap forward in additive manufacturing, as the printer, an AMCM M290-2 FLX, is equipped with twin 1.2 kW lasers that bring unprecedented capabilities to industrial 3D printing.

By leveraging nLIGHT’s advanced beam shaping technology, this next-generation system enables operators to modulate both the spot size and shape of the laser without sacrificing power or material density. The result is a more efficient and sustainable manufacturing process, with increased productivity and significantly reduced material waste.

A New Era in Industrial 3D Printing

Brian Neff, Founder and CEO of Sintavia, expressed his enthusiasm for this groundbreaking addition to the company’s fleet of printers. “We welcome this new addition to our fleet of printers,” Neff stated. “Over the coming years, as we develop and apply this new technology, we expect to be able to print our components at layer thicknesses of 150µm or more without losing any material properties, thus greatly increasing the output of our installed printers.”

The ability to print at such increased layer thicknesses without compromising material integrity is a major breakthrough. Currently, the standard layer thickness used in powder bed fusion (PBF) additive manufacturing ranges from 30µm to 45µm. The adoption of nLIGHT’s beam shaping laser technology allows manufacturers like Sintavia to effectively double or even triple this thickness, significantly accelerating the production process.

One of the most promising aspects of this technology is its retrofitting capability. According to Neff, once fully tested, the nLIGHT system can be integrated into existing EOS and AMCM printers with minimal new equipment. This feature means that manufacturers who already utilize similar systems can adopt this cutting-edge laser technology without a costly overhaul of their machinery.

Industry Experts Weigh In

The introduction of the first dual nLIGHT system in the U.S. has been met with excitement from industry leaders. Martin Bullemer, Managing Director of AMCM GmbH, highlighted the importance of Sintavia’s role in refining and expanding the capabilities of this revolutionary laser technology.

“We can think of no better home for the first dual nLIGHT system in the U.S. than Sintavia,” Bullemer said. “With their vertically integrated additive manufacturing capabilities, including extensive testing labs, they are well-suited to help develop and expand the capabilities of the nLIGHT laser beam shaping technology.”

This partnership between AMCM, nLIGHT, and Sintavia represents a strategic collaboration that will push the boundaries of what is possible in metal additive manufacturing, particularly for the aerospace industry, where material performance and efficiency are critical.

Advantages of nLIGHT Beam Shaping Lasers

Traditional laser systems used in powder bed fusion additive manufacturing rely on a Gaussian beam profile, which presents limitations in terms of efficiency and layer thickness capabilities. The introduction of nLIGHT’s beam shaping technology, however, offers a transformative improvement over this standard approach.

The key benefits of nLIGHT beam shaping fiber lasers include:

- Increased Build Speed – By enabling the melting of fully dense material at a diameter over three times greater than standard laser systems, manufacturers can significantly speed up production without sacrificing quality.

- Reduced Material Waste – The ability to print using fewer layers directly translates into less condensate generation, reducing waste by up to 70%. Condensate, a metal vapor jet produced during the PBF process, is one of the most problematic byproducts in additive manufacturing. By minimizing its formation, manufacturers can enhance sustainability and reduce maintenance challenges.

- Enhanced Material Performance – The ability to fully melt thicker build layers without losing density results in improved grain structure, particularly in the z-direction. This is especially beneficial for applications requiring high creep resistance, such as aerospace and defense components.

These advantages underscore the transformative potential of beam shaping lasers in advancing additive manufacturing. As Sintavia continues to refine its processes and integrate this cutting-edge technology into its operations, the impact on the broader industry will be profound.

Implications for Aerospace Manufacturing

The aerospace sector stands to benefit significantly from the adoption of advanced beam shaping laser technology. Aerospace components must meet rigorous performance and safety standards, and any innovation that enhances efficiency while maintaining or improving material integrity is highly valuable.

Sintavia’s integration of the AMCM M290-2 FLX printer with nLIGHT technology is expected to drive advancements in the design and production of aerospace components, reducing lead times and material waste while increasing overall efficiency. As the company continues to test and optimize this new system, it will provide valuable insights into how the technology can be implemented at scale across the industry.

Furthermore, by enabling thicker build layers without compromising material density or performance, nLIGHT lasers offer a cost-effective solution for manufacturers looking to maximize their production capabilities. This innovation could lead to more widespread adoption of additive manufacturing in aerospace, allowing for the creation of complex, high-performance components with greater efficiency than ever before.

The Future of Additive Manufacturing

Sintavia’s latest acquisition is a testament to the rapid evolution of additive manufacturing technologies and their growing role in industrial production. As the first company in North America to commission a multi-laser industrial 3D printer with nLIGHT beam shaping fiber lasers, Sintavia is at the forefront of this transformation.

The potential applications for this technology extend beyond aerospace. Industries such as automotive, medical, and energy could also benefit from the increased efficiency, reduced waste, and improved material performance that beam shaping lasers provide. As more manufacturers adopt this innovation, the impact on global production processes will become increasingly evident.

With Sintavia leading the charge, the future of additive manufacturing looks brighter than ever. By pushing the boundaries of what is possible with metal 3D printing, the company is setting new standards for efficiency, sustainability, and performance in the industry. As testing and development continue, the full potential of this revolutionary technology is yet to be realized—but the promise it holds is undeniable.