Aseptic Filling Machine Market Forecast to 2035 with Key Players

The “Aseptic Filling Machine Market Industry Trends and Global Forecasts to 2035” report, available through ResearchAndMarkets.com, offers a detailed forecast and insights into the aseptic filling machine market. The global market, valued at USD 1.3 billion in 2024, is projected to reach USD 3.4 billion by 2035, growing at a compound annual growth rate (CAGR) of 8.7% during this period. This growth is attributed to the increasing demand for precise and sterile pharmaceutical production methods and the rising number of biologics and injectable drugs in development.

The Importance of Aseptic Fill-Finish Manufacturing

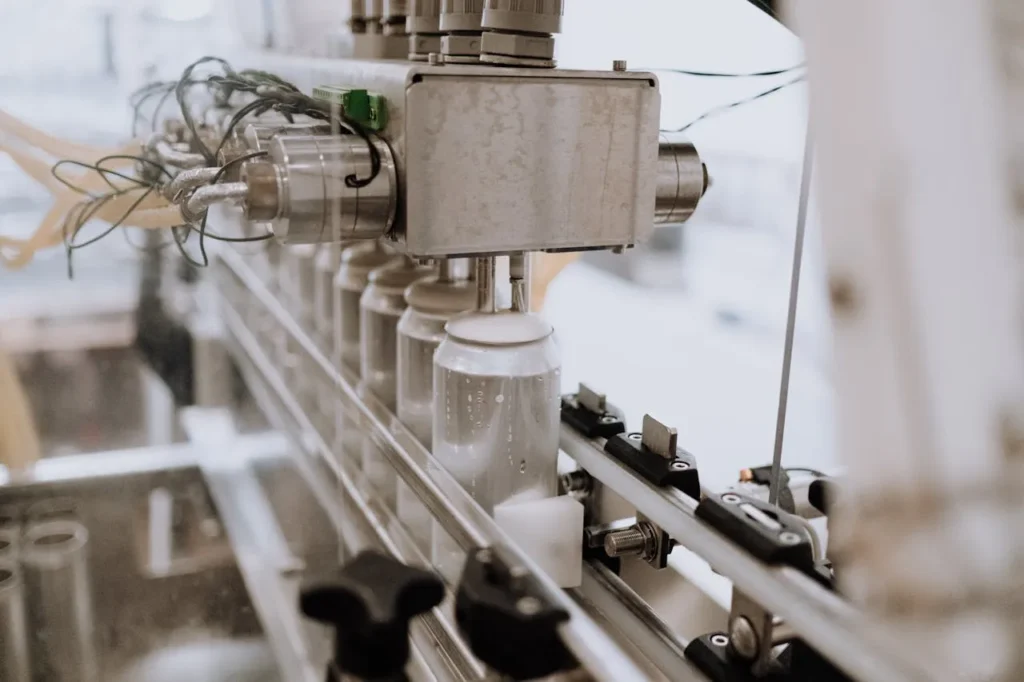

Aseptic fill-finish manufacturing is a critical aspect of pharmaceutical production. It involves the sterile filling of pharmaceutical products, such as drugs, into containers. However, the process faces several challenges, including contamination risks, inaccuracies in dose dispensing, and labeling issues. Research indicates that approximately 80% of product recalls are due to packaging-related errors, highlighting the need for more efficient and reliable filling processes. Furthermore, manual interventions during filling processes increase the risk of contamination, as human contact with products can compromise their integrity.

The Role of Isolators and Restricted Access Barrier Systems (RABS)

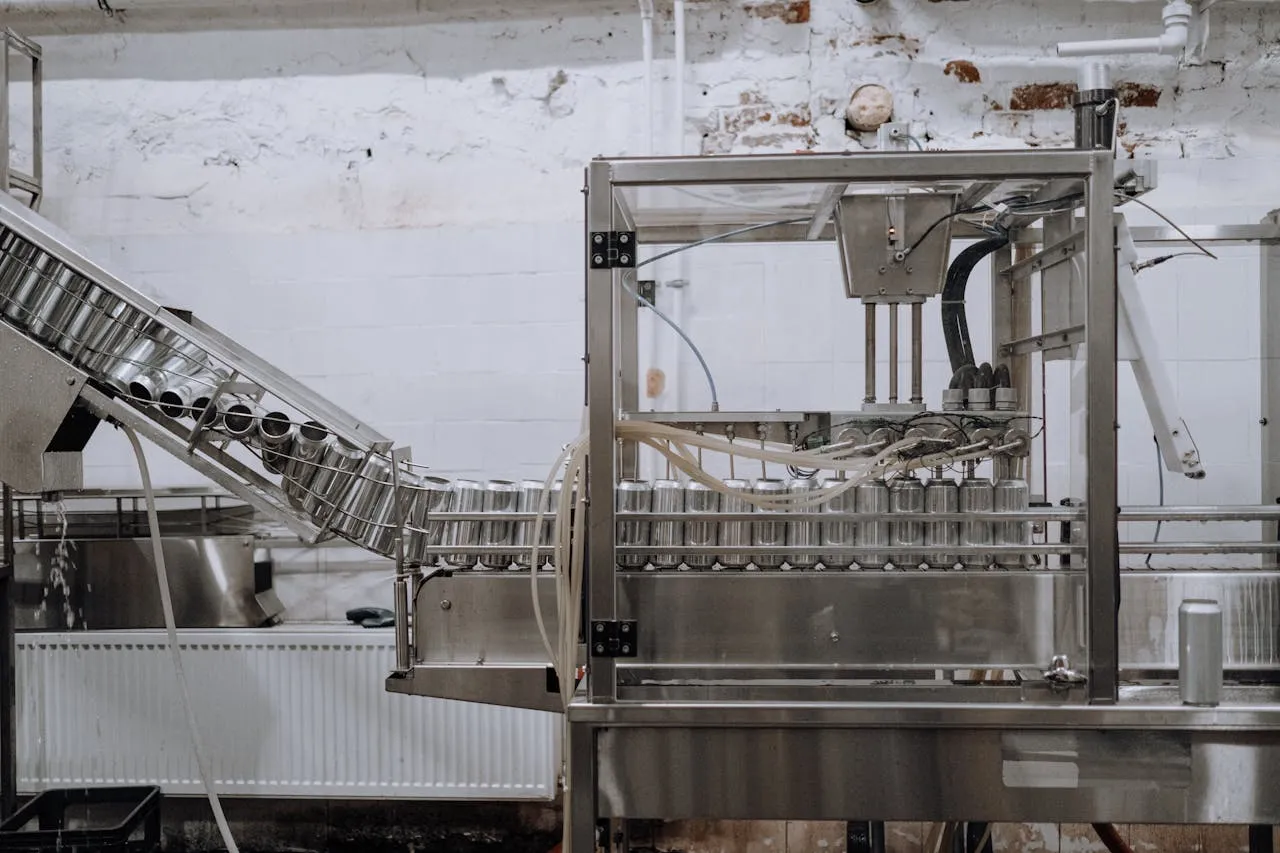

To address these challenges, pharmaceutical equipment manufacturers have increasingly introduced cost-effective and reliable machinery that integrates isolators and restricted access barrier systems (RABS). These systems are designed to minimize human involvement, reduce contamination risks, and improve operational efficiency. The use of isolators in aseptic filling lines allows for the isolation of equipment components, resulting in substantial cost savings. Manufacturers can avoid the need for large, high-end cleanrooms, as these systems can maintain sterile conditions without the need for extensive infrastructure.

As of now, more than 230 isolator-based aseptic filling and closing systems are available in the market. These systems are continuously being improved by developers to meet evolving industry standards and demands. The rise in the development of biologics and the increasing number of injectable drugs in the pharmaceutical pipeline are expected to drive further demand for aseptic filling machines in the coming years.

Key Insights into the Aseptic Filling Machine Market

The report identifies key trends and growth opportunities in the aseptic filling machine market. Several important findings are highlighted:

- Isolator-Based Systems: The majority of aseptic filling machines are isolator-based, with vials being the most commonly used primary container for these systems. Over 230 isolator-based aseptic filling machines are available, with 78% of them capable of both filling and closing operations for liquid or powder formulations. This is followed by systems designed solely for filling operations (15%).

- Fragmented Market Landscape: The market for isolator-based aseptic filling machines is fragmented, with a mix of new entrants and established players. The majority of these companies are based in Europe, but global expansion is ongoing.

- Automation and Innovation: Leading manufacturers are integrating advanced automation, real-time monitoring, and automated cleaning into their aseptic filling systems. These innovations are improving the overall efficiency of filling lines and driving market growth.

- Compliance with Industry Standards: Companies are investing in the upgrade of existing systems to comply with changing regulatory requirements and to enhance their fill-finish capabilities. These upgrades focus on improving the precision, speed, and safety of aseptic filling operations.

- Sustainability Trends: Recent mega trends, including automation and sustainability, are shaping the future of the isolator-based aseptic filling machine market. These trends are driving innovation in the industry, as stakeholders seek to enhance manufacturing processes while minimizing environmental impact.

- Rising Demand for Injectable Drugs: The increasing development of injectable drugs and pipeline candidates is further fueling the demand for aseptic filling machines, as the pharmaceutical industry requires precise and sterile packaging for these products.

Market Segmentation: Key Factors Driving Growth

The aseptic filling machine market is segmented based on several factors, including the type of compatible primary containers, scale of operation, system throughput, and end-users. Below are some key insights into each segment:

1. Primary Container Types: Vials Dominating, Cartridges Growing

The market is segmented by the type of primary container, with vials currently holding the largest market share. Vials offer significant advantages, such as the ability to pre-sterilize containers through terminal sterilization techniques, minimizing the risk of contamination during transportation and handling. These benefits make vials the most preferred option in the pharmaceutical industry. However, the cartridge segment is growing at a rapid pace due to the increasing demand for more specialized packaging solutions for certain drugs.

2. Scale of Operation: Commercial Scale to Dominate

The market is also divided by scale of operation, into clinical and commercial scale. The commercial scale segment is expected to dominate the market during the forecast period, as revenues from isolator-based aseptic filling machines operating at a commercial scale are expected to be the primary drivers of market growth. Commercial-scale production requires high throughput systems capable of efficiently filling and closing large quantities of pharmaceutical products.

3. System Throughput: High Throughput Leading the Way

System throughput refers to the speed at which filling machines can process pharmaceutical products. The market is segmented into low, medium, and high throughput systems. High throughput systems currently capture the largest share of the market, as both in-house manufacturers and contract manufacturing organizations (CMOs) rely on these machines to meet the demands of commercial-scale production. The ability to process large volumes of products at high speeds is a critical factor for manufacturers aiming to meet market demand.

4. End-Users: Pharma/Biotech Companies Leading Market Share

Pharma and biotech companies currently hold the largest share of the aseptic filling machines market. These companies are heavily investing in advanced filling technologies to improve the efficiency, safety, and compliance of their drug production processes. The rise in biologics and injectable drugs further drives demand for aseptic filling systems, as these products require sterile and precise filling operations.

5. Geographical Regions: Europe to Maintain Dominance

The market is also segmented by key geographical regions, including North America, Europe, Asia-Pacific, and the Rest of the World. Europe currently holds the largest share of the market and is expected to maintain this position throughout the forecast period. However, the market in Asia-Pacific and other regions is anticipated to grow at a higher CAGR, as emerging markets in these areas present new growth opportunities for manufacturers of aseptic filling machines.

Competitive Landscape and Key Players

The aseptic filling machine market is competitive, with several key players leading the market. Some of the leading companies in the market include:

- AST

- Bausch+Strobel

- Dara Pharma

- Groninger

- IMA Group

- Marchesini Group

- OPTIMA

- Syntegon

- Tofflon

These companies are actively innovating and enhancing their aseptic filling systems, integrating advanced technologies such as automation and real-time monitoring. Their ongoing efforts to improve the efficiency and reliability of aseptic filling machines are contributing to the growth of the market.

Regulatory Guidelines and Future Outlook

As the aseptic filling machine market continues to grow, regulatory guidelines are becoming increasingly important. Aseptic processing requires strict adherence to cleanroom standards, as well as specific guidelines for using isolator and blow-fill-seal technologies. Manufacturers must comply with these regulations to ensure the safety and efficacy of pharmaceutical products. The future of the aseptic filling machine market will be shaped by advancements in technology, evolving regulatory requirements, and the growing demand for biologics and injectable drugs.

The aseptic filling machine market is poised for significant growth, driven by advancements in technology, the rising demand for biologics and injectable drugs, and the increasing need for more efficient and reliable filling processes. With innovations in automation, real-time monitoring, and sustainable manufacturing practices, the market is expected to continue expanding throughout the forecast period. Manufacturers and stakeholders in the pharmaceutical industry must stay informed about the latest developments and trends to capitalize on the opportunities in this rapidly evolving market.