Curtiss-Wright’s Engineered Materials Solutions (EMS) Division has announced a significant milestone in the advancement of additive manufacturing (AM) technology in defense applications. The company, in collaboration with Bechtel Plant Machinery Inc. (BPMI) and Sintavia, LLC, has delivered the first submarine component featuring an additively manufactured (AM) impeller, set to be installed in a U.S. Navy vessel. This groundbreaking achievement marks a pivotal moment in the use of AM for naval defense, showcasing the potential of advanced manufacturing techniques in the creation of mission-critical components.

The project began with a close partnership between Curtiss-Wright’s Engineered Pump Division (EPD) in Bethlehem, PA, BPMI in Monroeville, PA, and Sintavia, a leader in the design and manufacture of additively produced defense components, headquartered in Fort Lauderdale, FL. These companies worked together to develop, manufacture, test, and supply the first-ever submarine component incorporating a qualified metal AM part. Sintavia, recognized for its cutting-edge expertise in the AM sector, provided the AM impeller after a thorough qualification process. Once delivered, the impeller was integrated into the pump and underwent rigorous testing at Curtiss-Wright’s facility in Bethlehem, ensuring it met the exacting standards required for naval operations.

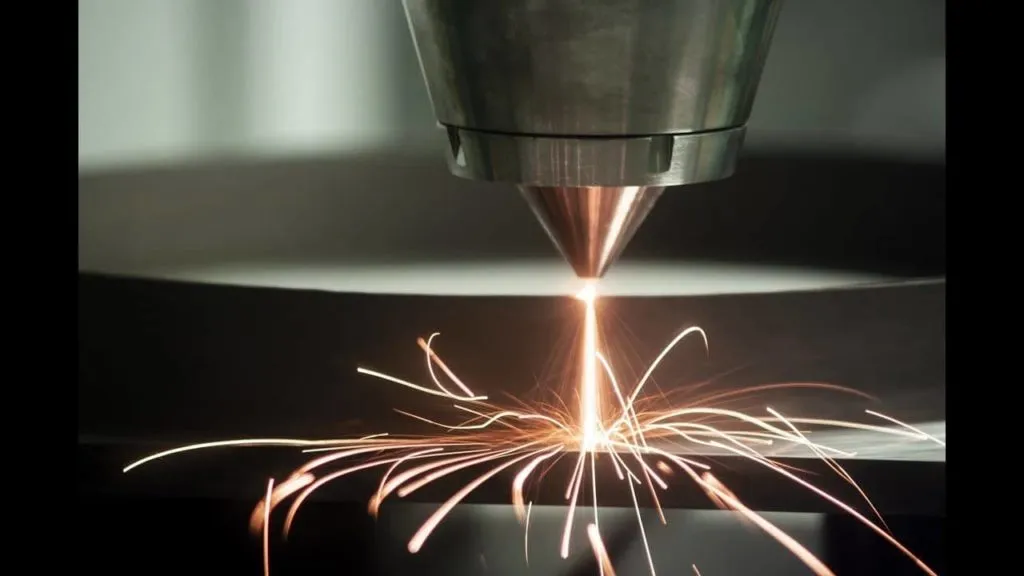

The use of additive manufacturing in this context offers numerous advantages over traditional manufacturing methods. Additive manufacturing, particularly in the defense industry, is rapidly becoming a solution for components that have been difficult, time-consuming, or prohibitively expensive to produce using conventional techniques. AM provides an opportunity to create complex parts with greater precision, reducing both material waste and production time. This is especially beneficial for defense applications, where fast and reliable sourcing of high-quality components is crucial.

With this breakthrough, the collaboration partners are also addressing the need for a dependable, domestic manufacturing capability. The U.S. Navy has long sought ways to reduce lead times, enhance component reliability, and improve overall system performance. AM technology offers a promising pathway to meeting these objectives. By adopting AM for critical components such as impellers, the partners aim to lower risks associated with component performance while improving delivery times for naval vessels. This collaboration reflects a broader commitment to advancing the U.S. Navy’s capabilities and ensuring it has access to the most advanced technologies available.

David Micha, Senior Vice President and General Manager of Curtiss-Wright’s EMS Division, expressed his enthusiasm for the partnership with Sintavia. He stated, “Sintavia has proven to be an invaluable industry partner, and we are excited about the opportunity to further solidify our relationship by increasing the number of additively manufactured parts for this application and other critical naval defense components.” Micha continued, “In addition, we are proud to be providing the first critical service equipment utilizing an additively manufactured component to the U.S. Navy’s submarine program and look forward to expanding these capabilities in the future to more efficiently serve our customer.”

Lindsay Lewis, Corporate Vice President at Sintavia, echoed this sentiment, highlighting the importance of AM technology in advancing defense capabilities. “We would like to thank both Curtiss-Wright and BPMI for the opportunity to leverage Sintavia’s additive technology in the production of this critical component,” Lewis said. “Leading-edge manufacturing processes such as AM will continue to be key differentiators in developing superior defense components in the years to come.”

Curtiss-Wright’s EPD business unit, a key player in Curtiss-Wright’s EMS Division, has a long history of delivering advanced technological solutions for the naval and maritime industries. Since 1847, Curtiss-Wright and its predecessor companies have been at the forefront of providing pumps and components for both surface and submerged naval fleets, meeting demanding mission-critical requirements. Today, EPD is a leading supplier of pumps, spare and replacement parts, composite components, and a range of support services, including overhaul and in-field expertise. As part of this legacy, Curtiss-Wright is committed to continually improving its product offerings and incorporating the latest manufacturing technologies to better serve its customers, including the U.S. Navy.

The successful integration of the additively manufactured impeller into the submarine component marks the beginning of a new era for advanced manufacturing in naval defense. The use of AM in military applications is expected to grow as it offers significant advantages in terms of component performance, delivery speed, and cost-efficiency. This project is not only a testament to the power of collaboration between industry leaders but also an indication of the future of defense manufacturing—one that increasingly relies on cutting-edge technologies like additive manufacturing to meet the evolving needs of the U.S. military.

For more information on Curtiss-Wright’s Engineered Pump Division and its capabilities, visit www.cw-ems.com/epd.