Recover™, a global leader in producing recycled cotton fiber and cotton fiber blends, is excited to announce the opening of its latest manufacturing facility in Vietnam, a significant step in its global expansion. The facility, expected to begin operations in early 2025, will be the cornerstone of the company’s strategy to advance large-scale sustainability in the rapidly growing Vietnamese textile production market. The location, in Dong Nai province, was carefully selected due to Vietnam’s pivotal role in the global textile industry, being the third-largest textile exporter worldwide.

By establishing this state-of-the-art facility, Recover™ is positioning itself close to both textile waste sorting operations and manufacturing hubs. This strategic proximity will reduce transportation costs and environmental impact while improving efficiency in supply chain logistics. It further strengthens the company’s ability to act as a true global partner to the textile industry, ensuring that brands in key textile production markets have timely access to high-quality recycled materials.

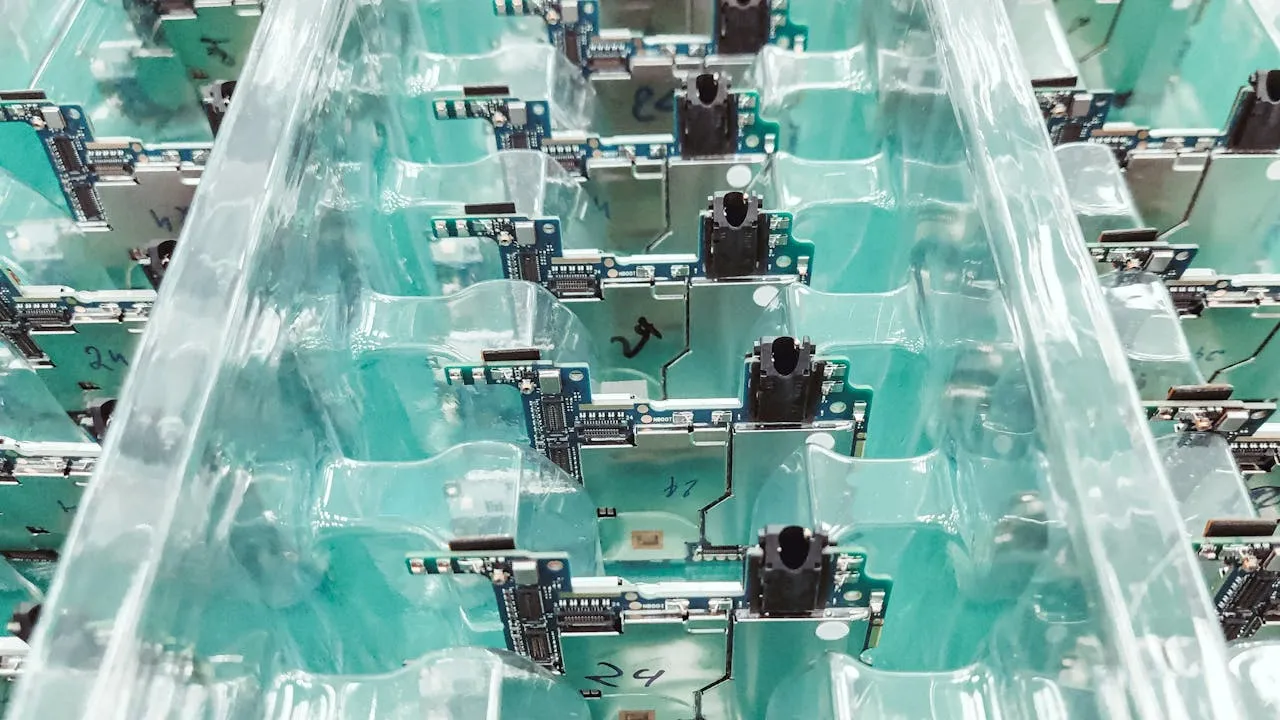

Covering almost 14,000 square meters, the new factory will be equipped with Recover™’s cutting-edge recycling technology, featuring two advanced recycling lines with an initial annual production capacity of 10,000 metric tons. The facility will also house a dedicated laboratory to monitor product quality and drive continuous improvements in both product offerings and operational processes. This commitment to innovation will ensure that Recover™ maintains the highest standards in quality, reinforcing the company’s reputation for excellence.

A primary focus of the factory will be the production of RMix, Recover™’s breakthrough recycling solution for cotton-polyester blends. This proprietary technology is revolutionary for the industry, as it eliminates the need to separate the fibers in mixed cotton-polyester fabrics—a long-standing challenge in the recycling process. By streamlining this complex process, Recover™’s technology not only improves energy efficiency but also enhances the sustainability of the recycling process, offering a considerable environmental advantage.

The decision to expand operations into Vietnam is a key element of Recover™’s strategic growth plan. Our expansion into Vietnam is a crucial step in our business strategy, said Anders Sjöblom, CEO of Recover™. “Circularity remains an underutilized concept in Vietnam’s textile industry. By introducing our advanced technology to this key textile hub, we aim to foster a shift toward more sustainable practices, benefiting not just our customers but also the broader textile industry in Vietnam.”

This new facility follows Recover™’s successful expansion into Bangladesh in 2022, where the company opened its second manufacturing plant. With this latest addition, Recover™ is firmly positioned to scale its operations globally, catering to the increasing demand for recycled materials from brands and retailers across the globe.

The Vietnam facility is part of the company’s broader vision to expand its reach to new international markets. As the demand for sustainable materials in the textile industry grows, Recover™ is committed to providing innovative, eco-friendly solutions that not only meet industry needs but also contribute positively to the circular economy.

With its track record of trust, sustainability, and technological leadership, Recover™ is elevating the standard for textile recycling. Through strategic investments in facilities like the one in Vietnam, the company is setting the stage for an even more sustainable future, helping the global textile industry reduce its environmental footprint one recycled fiber at a time.