Cyclic Materials, an advanced metals recycling firm dedicated to creating a circular supply chain for rare earth elements and other critical metals, has announced a new collaboration with SYNETIQ, an IAA company and the leading integrated vehicle salvage and recycling company in the U.K. The agreement focuses on recycling electric motors containing rare earth elements, including drive motors from hybrid and electric vehicles and auxiliary motors from all vehicles.

“This partnership marks Cyclic Materials’ first international feedstock contract and is a significant step as we expand our operations from North America into Europe in the coming months. SYNETIQ was an obvious choice for us due to our shared commitment to circular solutions for electric motors,” said Patrick Nee, Senior Vice President of Strategic Partnerships and Co-founder of Cyclic Materials. “This agreement represents a major advancement in our mission to promote sustainable rare earth recycling and advance the global circular economy. Together, we aim to drive industry-wide changes in electric motor recycling.”

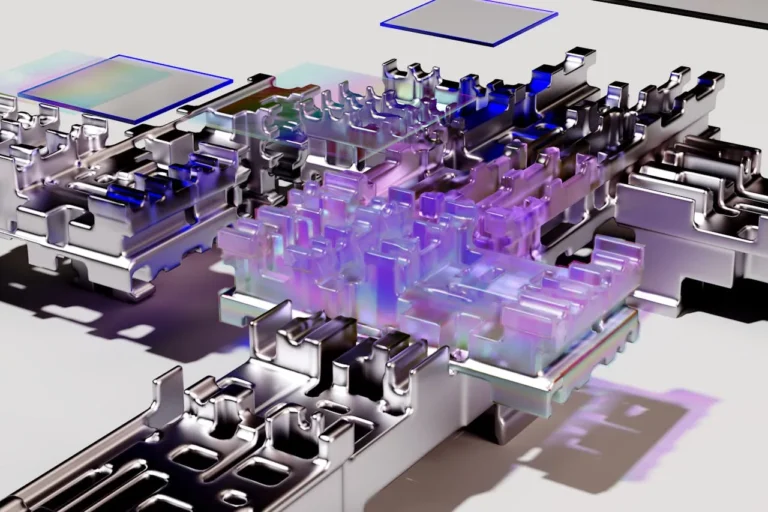

Founded in 2021, Cyclic Materials is at the forefront of developing technologies to economically and sustainably transform end-of-life (EOL) products into valuable raw materials. Recycling rare earths offers significant environmental benefits compared to traditional mining, including reduced carbon emissions and lower water usage. The company recently launched its “Hub100” commercial demonstration plant in Kingston, featuring its proprietary hydrometallurgical technology, REEPure, to meet the growing demand for domestic sources of mixed rare earth oxide (MREO) in North America.

Michael Hill, Commercial Director of SYNETIQ, stated, “We are thrilled to announce our new collaboration with Cyclic Materials. This partnership highlights our commitment to sustainability, innovation, and responsible practices at the core of our circular model.”

Cyclic Materials’ proprietary Mag-Cycle™ and REEPure™ technologies are the first globally to separate magnets from end-of-life products like electric motors and convert them into mixed rare earth oxides, cobalt-nickel hydroxides, and other raw materials. SYNETIQ’s feedstock will be processed at Cyclic Materials’ “spoke” facility using Mag-Cycle™ before being sent to the “Hub100” plant for further processing with REEPure™ technology.

Partnerships like this one with SYNETIQ enable salvage and dismantling yards to maximize the recovery of materials and value from hybrid and electric vehicles, as well as smaller motors in internal combustion engine vehicles.

For more information about Cyclic Materials, visit www.cyclicmaterials.earth.