GE Aerospace has unveiled a plan to invest over $1 billion in its component maintenance, repair, and overhaul (MRO) facilities globally over the next five years. This significant investment aims to bolster the company’s capacity to support the increasing demand for its wide- and narrow-body aircraft. The funds will be used to expand engine and equipment test cells and incorporate advanced technologies, such as innovative inspection techniques, to reduce turnaround times and enhance repair capacity.

Russell Stokes, President and CEO of GE Aerospace’s Commercial Engines and Services, emphasized the importance of this investment: “As air travel demand rises, we are committed to boosting our capacity and efficiency to meet our customers’ needs and ensure their aircraft operate safely and reliably. This investment underscores our dedication to safety, quality, and timely delivery.”

A significant portion of the investment will address the growing demand for CFM LEAP* engines. With over 3,300 LEAP-powered aircraft currently in service and more than 10,000 engines in backlog, this expansion will support the increase in the global commercial aircraft fleet.

Many of these investments are driven by employee-led initiatives aimed at enhancing safety, quality, delivery, and cost-efficiency through GE Aerospace’s proprietary lean operating model, FLIGHT DECK.

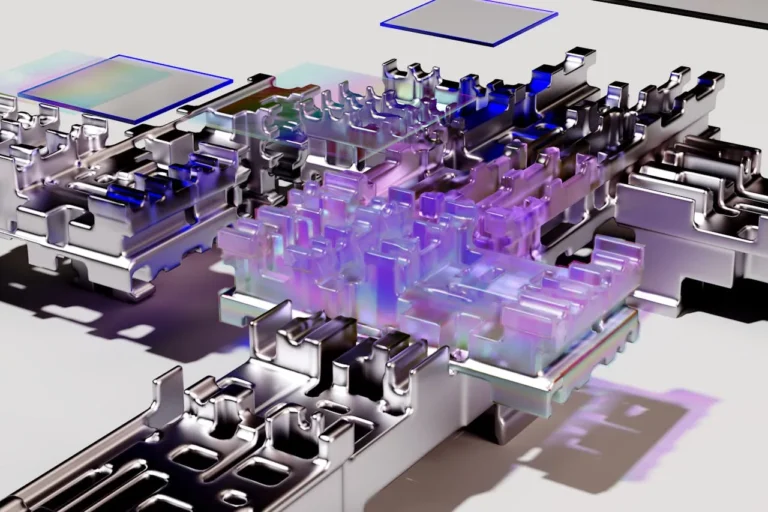

Key components of this year’s MRO funding include the construction of a new Service Technology Acceleration Center (STAC) in Cincinnati, Ohio, set to open in September 2024. The STAC will facilitate the rapid adoption of innovative service techniques, including advanced inspection technologies to identify issues earlier and minimize aircraft downtime.

In 2024, GE Aerospace will allocate $250 million of its planned five-year investment to regional repair and overhaul facilities worldwide, with funds earmarked as follows:

- United States: ~$65M (Cincinnati, Ohio; McAllen, Texas; Lafayette, Indiana; Dallas, Texas; Winfield, Kansas)

- South America: ~$55M (Petropolis, Brazil)

- Europe & Middle East: ~$60M (Budapest, Hungary; Prestwick, Scotland; London, England; Cardiff, Wales; Wroclaw, Poland; Doha, Qatar; Dubai, UAE)

- Asia Pacific: ~$45M (Singapore; Taipei, Taiwan; Kuala Lumpur, Malaysia; Seoul, South Korea)

GE Aerospace’s overhaul facilities manage over 40,000 commercial aircraft engines, providing services including engine disassembly, reassembly, maintenance, repair, inspection, and testing.

CFM International is a joint venture between GE Aerospace and Safran Aircraft Engines. LEAP is a registered trademark of CFM.