Tenaris is collaborating in the SafeH2Pipe Joint Industry Project (JIP) alongside five other leading steel and energy companies—CPW, OCAS, Rosen, Shell Global Solutions International B.V., GRTGaz, and EPRG—in partnership with RINA to develop new guidelines for material selection and qualification for the safe transportation of hydrogen and hydrogen blends through European pipelines. This JIP is one of several initiatives Tenaris is involved in to advance hydrogen material research.

Supported by the European Commission, SafeH2Pipe was launched to address the need for safe and cost-effective hydrogen transportation and storage for the upcoming hydrogen-based economy, receiving 60% of its funding from the Research Fund for Coal and Steel. With approximately 23,000 km of hydrogen pipelines expected in the European Union by 2040, there will be a gradual transition from adapting existing pipelines to constructing new ones. Given hydrogen’s unique properties, selecting and qualifying appropriate pipeline materials is crucial.

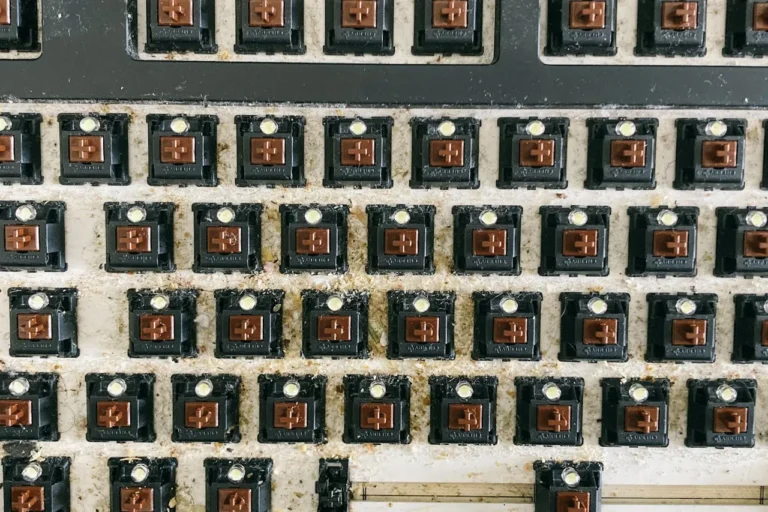

Representatives from the participating companies recently gathered at Dalmine, Tenaris’s seamless pipe mill in Italy, to evaluate the project’s progress. “This meeting was very useful to agree on some strategic points with our partners. Tenaris plays a strategic role as WP3 (Materials Supply) Project Leader; the project will examine samples from both new and old pipelines produced through diverse manufacturing methods, including welded pipes (both LSAW and HFI) and seamless pipes. Through state-of-the-art engineering studies, model and full-scale testing, and adopting a fitness-for-service approach, we will work on the material characterization of line pipes for hydrogen transportation, ensuring the highest safety and efficiency standards,” said Stefano Crippa, Technical Sales Product Manager for Pipeline at Tenaris.

“One of the things that makes this study particularly interesting is that through full-scale tests we are going to observe if and how hydrogen can affect line pipe performance in the presence of external defects, rather than the usually investigated internal defects. This is crucial because, given hydrogen’s ease of penetration into metal, the presence of external defects created by accidental mechanical damage can pose some serious risks,” highlighted Andrea Bufalini, RINA technical contact for the SafeH2Pipe project.

Learn more about Tenaris’s advanced product portfolio for the energy transition.