Nordson at The Battery Show Europe 2025: Powering Innovation in Battery Manufacturing

Join Nordson Corporation at The Battery Show Europe 2025, taking place from June 3–5 at Messe Stuttgart in Stuttgart, Germany. Visit us at booth 10-D40 to experience firsthand the future of battery manufacturing.

As Europe’s premier event for advanced battery technology and electric vehicle innovation, The Battery Show Europe 2025 promises to be the most influential gathering of its kind on the continent. Bringing together the full spectrum of the battery industry—from materials and components to cutting-edge manufacturing equipment and software—this year’s show is expected to draw thousands of industry leaders, engineers, researchers, and OEM representatives.

For Nordson Corporation, a global leader in precision technology solutions for dispensing, coating, and processing applications, the event presents an ideal opportunity to highlight new advancements in battery manufacturing technologies designed to meet the growing global demand for electric vehicles (EVs) and energy storage systems (ESS).

Why The Battery Show Europe Matters

As the electrification of transportation continues to accelerate worldwide, manufacturers and suppliers are under increasing pressure to innovate. Europe, in particular, is emerging as a central hub for battery research and production, driven by the EU’s aggressive climate goals, growing consumer demand for EVs, and a wave of gigafactory investments. According to recent industry projections, the European EV battery market is expected to exceed €250 billion by 2030.

The Battery Show Europe provides an essential platform for companies like Nordson to collaborate, share insights, and showcase the solutions that will shape the future of battery production. Over three packed days, attendees will engage in technical sessions, keynote presentations, and hands-on demonstrations—gaining practical, actionable knowledge while exploring the latest innovations across the battery supply chain.

Spotlight on Nordson Industrial Coating Solutions (ICS)

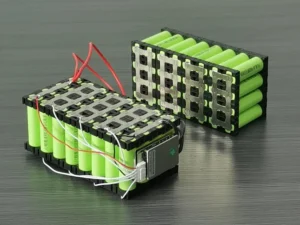

Nordson Industrial Coating Solutions will feature several key technologies that are enabling greater precision, speed, and durability in battery pack manufacturing—especially for high-performance sealing and bonding applications.

Pro-Meter® S PLC with Rhino® XD3 and ScoreGuard®

One of the centerpieces of the ICS showcase is the Pro-Meter® S PLC, an advanced system engineered for high-speed sealant dispensing. Ideal for automated production lines, the Pro-Meter S PLC ensures repeatable, high-volume output with excellent control and reliability—critical for sealing battery modules and enclosures in EV and ESS applications.

To support bulk dispensing needs, the Rhino® XD3 Bulk Unloader will also be featured. Designed for rugged industrial environments, the XD3 offers smooth, high-flow performance, reducing downtime while improving operator ergonomics and system longevity.

Adding to the durability and lifecycle advantages, Nordson integrates ScoreGuard® coating, a proprietary wear-resistant coating that enhances the resilience of internal pump components. In high-throughput EV battery assembly environments, minimizing component wear translates directly into better uptime and lower total cost of ownership.

Micro-Meter® D2K: Precision in Two-Component Dispensing

Also on display will be the Micro-Meter® D2K, a dual-servo, two-component dispensing system leveraging positive displacement technology. This system is ideal for applications requiring exact mix ratios and consistent volumetric output, such as bonding battery cells into packs or sealing enclosures.

The Micro-Meter D2K is particularly beneficial for thermal interface materials (TIMs), structural adhesives, and other reactive chemistries that must be precisely mixed and metered. With fully programmable control, the D2K helps reduce material waste, ensures repeatable results, and facilitates easier validation in regulated manufacturing environments.

Introducing Nordson Product Assembly’s Next-Gen Solutions

To meet the complex challenges of next-generation battery pack architectures, Nordson Product Assembly is unveiling new dispensing technologies engineered specifically for cell-to-pack (CTP) configurations and energy storage system applications.

As automakers transition from traditional cell-to-module-to-pack (CTMTP) designs toward integrated CTP designs to reduce weight and increase energy density, manufacturers require sealing and bonding technologies that can adapt to intricate geometries and tight tolerances.

Nordson’s latest offerings are designed to deliver:

- High-speed application with reduced cycle times

- Consistent bead geometry and placement accuracy

- Material compatibility with a wide range of adhesives and sealants

- Low maintenance requirements for long production runs

These systems are aligned with the automotive industry’s drive for modularity, scalability, and automated process integration. Whether for EV battery packs, energy storage racks, or hybrid modules, Nordson’s solutions ensure faster production without compromising quality or safety.

Nordson Measurement & Control Solutions: Enabling Process Transparency

Precision and quality control are essential in lithium-ion battery production. That’s where Nordson Measurement & Control Solutions (M&CS) comes in. At The Battery Show Europe 2025, Nordson M&CS will present the Photon™ Measurement System, a state-of-the-art solution that offers real-time monitoring of critical process parameters.

Photon™ Measurement System: High Accuracy in Coating Control

The Photon system is designed to measure coating weight and thickness with unparalleled accuracy. In battery cell production, particularly during electrode coating and separator film processing, even minute inconsistencies can lead to performance degradation or safety risks. Photon addresses these challenges with:

- Non-contact, high-resolution sensors

- Real-time data acquisition and analytics

- Closed-loop feedback integration for process automation

The result is improved yield, reduced material waste, and enhanced traceability—factors that are increasingly important in meeting the stringent quality and safety standards for EV batteries.

Rolling Mill Thickness Measurement

In addition to coating control, Nordson M&CS will demonstrate thickness measurement solutions used in the rolling mill stage of battery production. Maintaining uniform electrode thickness during the calendaring process is critical to achieving consistent battery capacity, energy density, and thermal performance.

Nordson’s inline gauging systems use high-precision sensors and advanced algorithms to detect variations in real time, allowing for on-the-fly adjustments that optimize product quality and reduce rework. These systems support both electrode and foil production, helping manufacturers maintain tight tolerances across large-scale production lines.

Meeting Global Challenges with Local Solution

With operations in more than 35 countries, Nordson is uniquely positioned to serve both global OEMs and local battery manufacturers. As Europe continues its push to localize battery production through initiatives like the European Battery Alliance and NextGenerationEU, Nordson’s regional support infrastructure ensures that customers have access to technical expertise, spare parts, training, and service when and where they need it.

From consultation and customization to implementation and after-sales support, Nordson partners with manufacturers to optimize every step of the production process. This collaborative approach not only reduces time-to-market for new battery designs but also helps ensure long-term process reliability and scalability.

A Sustainable Future, Engineered with Precision

Battery manufacturers are not only focused on performance and scalability—they’re also under pressure to improve sustainability. Nordson’s equipment is designed with this in mind. Many of the systems on display at The Battery Show Europe 2025 emphasize:

- Material efficiency, reducing waste through accurate metering and dispensing

- Energy-efficient operations, minimizing power usage without sacrificing throughput

- Extended equipment lifecycles, with wear-resistant components and modular design

- Process transparency, supporting better documentation and traceability in ESG reporting

These capabilities support manufacturers in achieving their environmental, social, and governance (ESG) goals, while also improving operational performance and profitability.

Nordson at Booth 10-D40

Attendees of The Battery Show Europe 2025 are invited to visit Nordson at booth 10-D40 to see live demonstrations, engage with product experts, and explore solutions tailored to their specific manufacturing needs. Whether you’re focused on launching a new gigafactory, retrofitting an existing line, or optimizing material usage, Nordson’s suite of technologies can help you reach your goals.

Key takeaways for visitors:

- Learn how to maximize uptime and throughput with advanced sealant and adhesive dispensing

- Discover precision measurement tools that ensure consistent product quality

- Explore new solutions for CTP and ESS applications

- Get advice from Nordson’s experienced engineering and technical teams