3D Printing Market Trends & Key Players Report – ResearchAndMarkets.com

The “3D Printing – Market Dynamics & Company Insights” report has been added to ResearchAndMarkets.com’s offering, providing an in-depth analysis of the global 3D printing market. The report explores the industry’s growth trajectory, technological advancements, and the expanding applications of 3D printing across multiple sectors. It offers a detailed evaluation of key drivers, restraints, competitive landscapes, and company insights, including both established market players and emerging startups.

3D Printing Market Overview

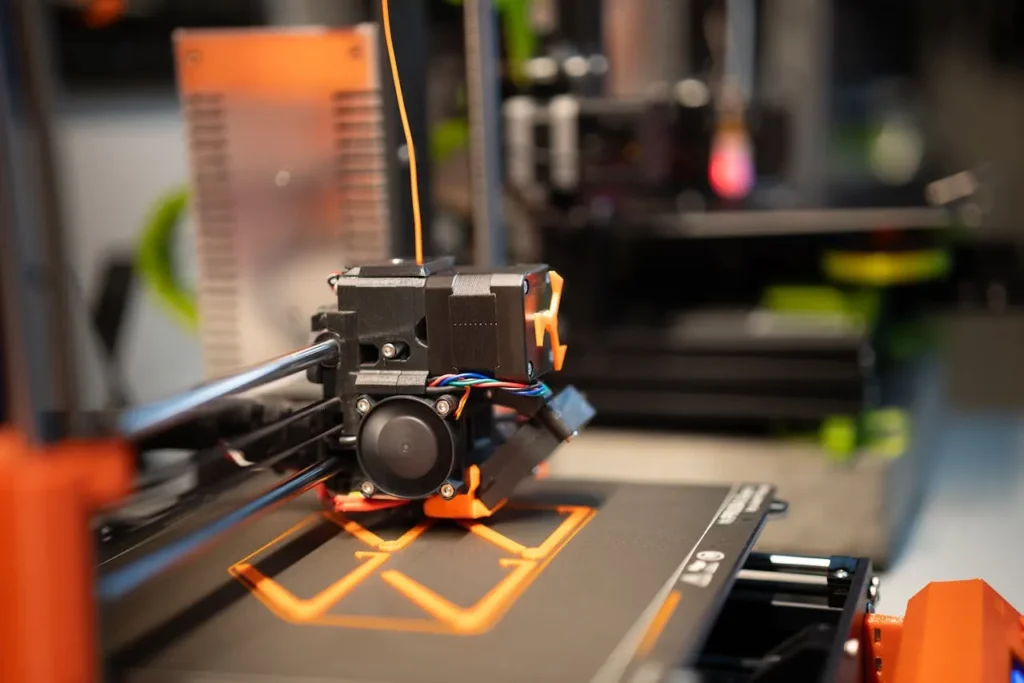

3D printing technology is redefining the way industries approach manufacturing, prototyping, and supply chain management. With its ability to create complex structures with high precision and minimal waste, 3D printing has gained substantial traction in industries such as aerospace, automotive, healthcare, and consumer goods. As a result, this market is expected to witness significant growth, fueled by advancements in material science, software development, and process optimization.

Market Dynamics

Key Drivers: Ease in Manufacturing Customized Products

One of the primary advantages of 3D printing technology is its ability to manufacture highly customized products efficiently. Unlike traditional manufacturing methods, which require expensive molds and tooling, 3D printing enables manufacturers to produce intricate designs on demand. This capability is particularly beneficial for industries requiring unique, customer-specific designs, such as healthcare (custom prosthetics and implants) and aerospace (lightweight structural components). Additionally, this flexibility reduces waste, lowers inventory costs, and enhances production efficiency.

Key Restraints: High Material Costs

Despite its numerous advantages, the high cost of 3D printing materials remains a significant barrier to widespread adoption. Specialized polymers, metals, and composite materials used in 3D printing are often more expensive than traditional manufacturing materials. Furthermore, the need for precise formulations to ensure optimal performance adds to production costs. This financial challenge is especially prominent in cost-sensitive industries such as consumer goods and construction, where affordability is a key factor in technology adoption.

Key Challenges: Ensuring Consistent Quality

Maintaining consistent quality in 3D-printed products is a persistent challenge. Unlike traditional manufacturing techniques, where quality control measures are well-established, 3D printing processes often face variability in print accuracy, material properties, and surface finish. This issue is particularly concerning for industries like aerospace and healthcare, where stringent quality standards must be met. The ongoing development of industry-wide standards and advanced quality control systems is crucial to overcoming these challenges.

Opportunities: Post-Pandemic Demand for Medical Products

The COVID-19 pandemic demonstrated the critical role of 3D printing in addressing urgent medical needs. The rapid production of ventilator components, personal protective equipment (PPE), and medical implants during the crisis highlighted the technology’s potential in the healthcare industry. Moving forward, 3D printing is expected to play an essential role in personalized medicine, including patient-specific implants, bioprinting of tissues, and pharmaceutical applications.

Competitive Landscape

The global 3D printing market is characterized by a combination of established corporations and innovative startups. Market leaders such as Stratasys, 3D Systems, HP, and EOS GmbH dominate due to their advanced product offerings and continuous investment in research and development. Meanwhile, startups such as Xometry and Proto3000 are gaining traction by focusing on niche applications and enhancing manufacturing efficiency.

Key Players:

- Stratasys: A leader in polymer 3D printing solutions, Stratasys is widely recognized for its advancements in material science and applications in industries such as automotive, aerospace, and healthcare.

- 3D Systems, Inc.: A pioneer in 3D printing, 3D Systems specializes in precision manufacturing and caters primarily to healthcare and aerospace sectors.

- HP Development Company: HP has made significant strides in 3D printing through its proprietary Multi Jet Fusion technology, which enhances production speed and quality.

- EOS GmbH: A leading provider of industrial-grade metal 3D printers, EOS is known for its applications in aerospace, automotive, and medical implants.

- General Electric (GE): Through its subsidiary GE Additive, the company focuses on industrial 3D printing solutions, particularly in the aviation sector.

- Materialise: This company offers software solutions and customized 3D printing services, with strong applications in the healthcare industry.

- Desktop Metal, Inc.: A company focused on advancing metal 3D printing technology for mass production, enabling cost-effective manufacturing of complex metal parts.

- Voxeljet AG: Specializing in industrial 3D printing systems, Voxeljet is widely used in the automotive and foundry industries.

- SLM Solutions: A leader in selective laser melting (SLM) technology, SLM Solutions focuses on high-performance metal parts for aerospace and automotive applications.

- Renishaw: Known for its high-precision metrology and additive manufacturing solutions, Renishaw serves industries requiring tight tolerances and exceptional quality.

Notable Startups:

- Xometry: This startup provides an advanced manufacturing platform that integrates 3D printing with CNC machining, injection molding, and sheet metal fabrication.

- Proto3000: Focused on dental and medical 3D printing applications, Proto3000 delivers high-precision, customizable solutions.

Evaluation Matrix

To assess the competitive positioning of companies in the market, an evaluation matrix is utilized. This matrix ranks firms based on their technological innovation, market reach, and financial stability. Companies are categorized as:

- Progressive Companies: Established players that continuously innovate while leveraging traditional manufacturing expertise.

- Responsive Companies: Businesses that quickly adapt to evolving market demands and technological advancements.

- Dynamic Companies: Startups and mid-sized firms that push the boundaries of applications.

- Starting Blocks: Emerging companies with high potential but limited market penetration.

Market Trends and Future Outlook

The 3D printing industry is poised for continued expansion, driven by technological advancements and increasing adoption across industries. Key trends shaping the market include:

- Advancements in Material Science: Development of new materials, including biodegradable polymers and high-performance metals, is expanding the technology’s applications.

- Integration with AI and Machine Learning: AI-driven design optimization and automated quality control are improving print efficiency and accuracy.

- Expansion in Aerospace and Defense: The demand for lightweight, high-strength components is accelerating the adoption of these sectors.

- Growth in Healthcare Applications: Personalized medicine, bioprinting, and custom implants are becoming mainstream applications of in healthcare.

- Rise of Sustainable Manufacturing: Eco-friendly and waste-reducing solutions are gaining prominence as industries focus on sustainability.

The 3D printing market in 2024 is a dynamic and evolving landscape filled with opportunities and challenges. Companies that focus on innovation, cost-efficiency, and strategic partnerships will be well-positioned for success. As the technology continues to mature, standardization and quality control measures will play a crucial role in driving widespread adoption. The insights provided in this report serve as a valuable resource for stakeholders looking to navigate the complexities of the industry and capitalize on emerging trends.