Industrial Robotics Report 2025: From Automation to Autonomy – AI, Humanoids, and Collaborative Robots Redefine the Future of Manufacturing

The latest “Industrial Robots” report from ResearchAndMarkets.com delivers an in-depth examination of how industrial robotics is undergoing one of its most transformative eras. The study highlights the powerful convergence of artificial intelligence (AI), computer vision, digital twins, and advanced actuation technologies that are accelerating the shift from automated to autonomous manufacturing systems.

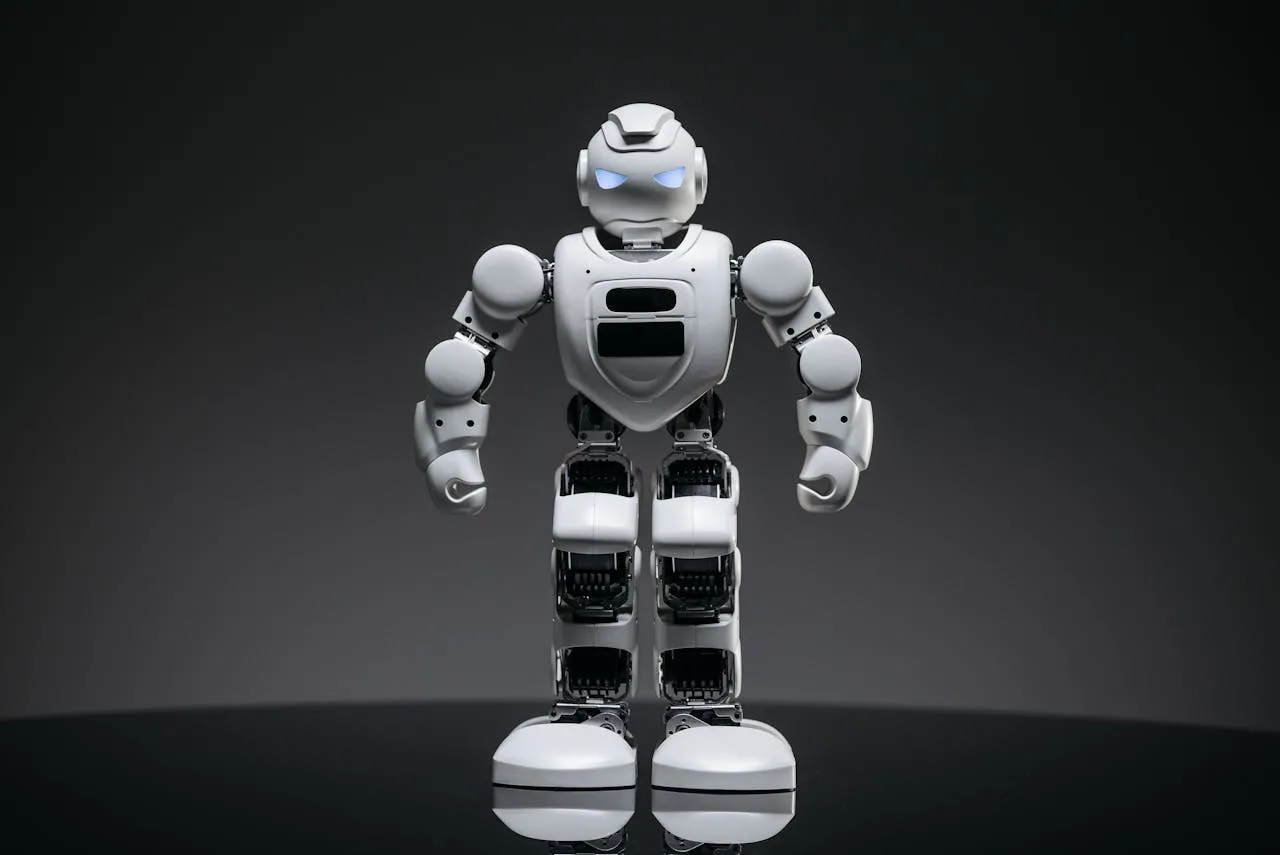

Across global industries—from automotive and electronics to healthcare and logistics—robots are no longer confined to fenced assembly lines. Instead, they are becoming intelligent, mobile, and increasingly humanoid, capable of working alongside humans with adaptive precision and contextual awareness. The report captures this evolution, emphasizing how the rise of intelligent robotics is redefining industrial productivity, safety, and collaboration.

From Automation to Autonomy: A Paradigm Shift

Industrial robotics has entered a new phase of transformation. What began decades ago as rigid, pre-programmed automation has evolved into flexible and learning-based autonomy. The latest generation of robots can perceive their environment, adjust to unexpected conditions, and perform complex tasks without constant human oversight.

This evolution is largely driven by AI integration, enabling robots to analyze data, improve through reinforcement learning, and adapt to dynamic environments. The result is a new category of autonomous robotic systems that can execute intricate manufacturing processes, optimize logistics, and even assist in healthcare or construction tasks with minimal intervention.

The report highlights how established players and startups alike are pushing the frontier of autonomy. BMW, Mercedes-Benz, and Tesla are piloting humanoid robots within their assembly and logistics operations, testing their capabilities for high-precision, repetitive, and ergonomically challenging tasks. ABB, FANUC, and KUKA continue to lead with collaborative and modular robotic arms, while startups such as Figure AI, Agility Robotics, and Apptronik are pioneering human-robot collaboration through advanced humanoid systems.

Market Acceleration and Investment Landscape

Momentum in the robotics industry has never been stronger. The report notes that the total deal value for robotics-related investments surged to $7.3 billion in the first half of 2025, fueled by major venture capital rounds, private equity participation, and corporate partnerships.

Patent activity reached its peak in mid-2024, reflecting an intense period of innovation focused on dexterity, actuator efficiency, battery optimization, and learning algorithms. These technological breakthroughs are now moving from R&D labs into factories and logistics hubs.

At the same time, hiring demand for robotics engineers and AI specialists has begun to stabilize, signaling that the sector is maturing from experimentation to large-scale deployment. Investments are increasingly targeting humanoid and mobile robotics, where advancements in motion control, perception, and energy management promise to unlock new industrial applications.

Expanding Applications and Sectoral Adoption

The adoption of industrial robots is expanding rapidly but unevenly across industries. Traditional strongholds—automotive, electronics, and aerospace—remain at the forefront, yet new sectors are gaining ground.

Healthcare facilities are employing robotic exoskeletons and surgical assistants to improve precision and ergonomics. The construction sector is testing robotic 3D printers and drywall automation systems, while the logistics industry is deploying autonomous mobile robots (AMRs) for warehouse management and last-mile delivery. Even retail and mining are exploring robotics for operational efficiency and safety enhancement.

However, small and medium-sized enterprises (SMEs) still face adoption barriers, including high capital expenditures, integration complexity, and limited technical skills. The report emphasizes that as costs decline and AI-driven usability improves, SMEs will become a crucial growth driver for industrial robotics adoption between 2025 and 2030.

Technologies Powering Next-Generation Robots

The foundation of modern industrial robotics lies in a fusion of technologies. The report details how AI, machine vision, IoT connectivity, digital twins, and advanced sensors are combining to create more adaptive and intelligent systems.

These technologies allow robots to interpret complex visual data, map their surroundings, and optimize their operations in real time. Meanwhile, digital twin technology enables continuous simulation and performance optimization by mirroring real-world production environments in virtual space.

Breakthroughs in actuators and energy systems have also improved payload capacity, endurance, and energy efficiency. Reinforcement learning allows robots to “train” themselves in dynamic settings, while improved software frameworks support interoperability between different robotic platforms.

This convergence is turning industrial robots into fully integrated elements of the digital factory ecosystem—capable not just of automation, but of decision-making and collaboration.

Innovation Moves from Hype to Deployment

The industrial robotics sector is shifting decisively from hype to real-world implementation. Robots are increasingly embedded within supply chains and digital manufacturing ecosystems.

The report cites several high-profile deployments:

- BMW and Mercedes-Benz have begun testing humanoid robots for assembly tasks, material handling, and logistics support.

- Tesla continues to advance its Optimus humanoid prototype for production environments.

- ABB and KUKA are expanding their modular cobot lines designed for safe, close-proximity collaboration.

- Agility Robotics’ Digit and Apptronik’s Apollo models are being evaluated for warehouse automation and parts delivery.

These examples signal a turning point where robotics moves beyond research labs and pilot phases into the core of industrial operations.

Key Findings from the Report

- Adoption Momentum: Intelligent robots—collaborative, mobile, and humanoid—are transforming manufacturing, logistics, and even healthcare.

- Technology Convergence: AI, reinforcement learning, machine vision, and digital twins form the foundation of the next generation of autonomous robots.

- Investment Strength: With $7.3 billion in deal value recorded in H1 2025, investor confidence remains strong, especially in humanoid robotics.

- Sectoral Growth: While automotive and electronics dominate, industries like construction, logistics, and healthcare are catching up rapidly.

- Barriers to Scale: High CapEx, safety certification, and integration complexity remain challenges, though they are increasingly offset by AI-driven cost efficiency and government automation incentives.

- Strategic Outlook: Robotics is central to digital transformation, reshoring efforts, and sustainability-driven manufacturing modernization.

Competitive and Innovation Landscape

The report offers extensive competitive intelligence covering both global leaders and emerging disruptors. Established companies like ABB, FANUC, KUKA, and Universal Robots continue to refine high-precision articulated robots and collaborative systems. Meanwhile, innovators such as Figure AI, Agility Robotics, Boston Dynamics, and Apptronik are introducing humanoid and AI-native platforms capable of human-like movement and decision-making.

Over 80 robotics innovations are highlighted in the report, spanning aerospace inspection systems, AI-guided surgical robots, warehouse automation, and construction robotics. The pace of technological diffusion shows that industrial robotics is becoming increasingly democratized, with use cases now spanning nearly every sector of the economy.

The report concludes with actionable insights for industry leaders, investors, and policymakers seeking to leverage robotics for competitive advantage. It recommends prioritizing R&D partnerships, expanding pilot programs into full-scale deployments, and aligning automation strategies with workforce reskilling initiatives.

Governments and industry associations are also urged to foster public-private partnerships and incentives to accelerate adoption, especially among SMEs. Workforce transition strategies—training human workers to collaborate effectively with robots—will be critical to maximizing productivity and social acceptance of intelligent automation.

By 2030, industrial robots are projected to be key enablers of smart manufacturing ecosystems, driving productivity gains, sustainability improvements, and enhanced supply chain resilience. As AI, autonomy, and human-robot collaboration converge, manufacturing will increasingly rely on robotic systems that can learn, adapt, and evolve alongside human operators.

The Industrial Robots Report 2025 provides an authoritative view of how robotics is reshaping the industrial world—from factory floors to logistics centers and beyond. The journey from automation to autonomy marks a new industrial revolution powered by AI, humanoid systems, and collaborative innovation.

As industrial robotics matures, it is no longer a futuristic vision—it is the foundation of the next generation of intelligent manufacturing, transforming how goods are produced, moved, and delivered across the global economy.